Select Your Region

Tribology 101: Understanding the Science Behind Lubrication

The Hidden Cost of Lubrication Decisions

Every plant manager faces a deceptively simple question: what lubricant should I use? But behind this question lies a complex web of consequences that impact your bottom line far beyond the price per gallon. Equipment failures, unplanned downtime, excessive energy consumption, and premature component replacement can transform what seemed like a cost-saving purchasing decision into a financial liability.

Tribology—the science of friction, wear, and lubrication—holds the answer to reducing these hidden costs. Yet many manufacturing facilities still approach lubrication as a commodity purchase rather than a strategic maintenance decision. The result? Plants spend 3-5% more on maintenance costs than necessary, with lubrication-related failures accounting for up to 50% of all equipment breakdowns.

The real question isn’t “what’s the cheapest lubricant?” It’s “what’s the true total cost of ownership for my lubrication program?”

Core Benefits: Why Strategic Lubrication Matters

1. Reduced Equipment Downtime and Extended Asset Life

Proper lubrication can extend equipment life by 50-200%, depending on the application. When you select lubricants engineered for your specific operating conditions—whether that’s extreme temperatures, chemical exposure, or high-pressure environments—you create a protective barrier that prevents metal-to-metal contact, reduces wear, and maintains optimal performance. The difference between a bearing lasting 2 years versus 5 years isn’t just about replacement costs; it’s about the production time saved and the maintenance labor hours redirected to value-added activities.2. Energy Efficiency Gains

Friction is the enemy of efficiency. Poor lubrication choices can increase energy consumption by 5-15% in rotating equipment alone. Advanced synthetic lubricants and specialty greases reduce friction coefficients, allowing machinery to operate more efficiently. In a facility running 24/7, even small efficiency improvements translate to substantial annual energy savings. For a mid-sized manufacturing plant, optimizing lubrication can reduce electricity costs by $50,000-$150,000 annually.3. Simplified Inventory and Reduced Complexity

Many plants stock 50-100 different lubricants, creating inventory management challenges, potential misapplication risks, and unnecessary carrying costs. A strategic lubrication program built on high-performance, multi-application products can consolidate your inventory by 30-60%, reducing storage requirements, minimizing ordering complexity, and decreasing the risk of using the wrong product in critical applications.4. Enhanced Safety and Regulatory Compliance

Specialty lubricants designed for oxygen-rich environments, food-grade applications, or high-purity processes aren’t just about performance—they’re about safety and compliance. Using oxygen-safe lubricants in compressed air systems prevents catastrophic fires. NSF-certified products protect your food safety certifications. Chemically stable formulations prevent dangerous reactions in aggressive environments. The cost of non-compliance—whether it’s a safety incident, regulatory fine, or product recall—dwarfs any savings from cheaper alternatives.5. Predictable Maintenance Scheduling

When lubricants perform consistently across temperature ranges, load conditions, and operating speeds, maintenance becomes predictable. You can plan relubrication intervals, schedule maintenance during planned downtime, and avoid the chaos of emergency repairs. This predictability reduces overtime costs, improves spare parts management, and allows your maintenance team to work strategically rather than reactively.Applications & Use Cases:Where Advanced Lubrication Makes the Difference

Understanding where specialty lubricants deliver maximum value helps you prioritize your lubrication strategy:

Extreme Temperature Environments

From automotive paint ovens operating at 500°F to cold storage facilities at -40°F, standard mineral oils fail rapidly. High-temperature synthetic lubricants maintain viscosity and prevent oxidation in heat-intensive processes, while low-temperature formulations stay fluid and pumpable in frigid conditions. Industries including steel production, glass manufacturing, aerospace, and food processing rely on temperature-resistant lubricants to maintain continuous operations.

Chemical Processing and Aggressive Environments

Chemical plants, pulp and paper mills, water treatment facilities, and industrial cleaning operations expose lubricants to acids, bases, solvents, and oxidizing agents. Chemically stable synthetic lubricants resist degradation, preventing equipment corrosion and maintaining lubrication performance even when exposed to harsh process chemicals. This stability eliminates the need for frequent relubrication and protects expensive pumps, valves, and mixing equipment.

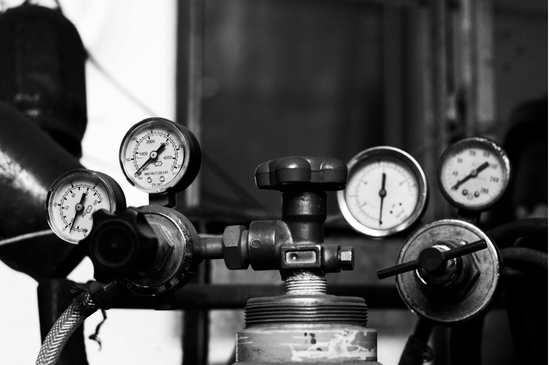

High-Pressure and Heavy-Load Applications

Mining equipment, construction machinery, metalworking presses, and industrial gearboxes operate under extreme pressures that would squeeze conventional lubricants out of load-bearing surfaces. Extreme-pressure (EP) greases and high-viscosity-index oils maintain film strength under load, preventing scoring, galling, and premature wear in critical components.

Clean Room and Food-Grade Applications

Pharmaceutical manufacturing, semiconductor fabrication, food and beverage production, and medical device assembly require lubricants that won’t contaminate products. NSF H1-certified food-grade lubricants, silicone-based formulations for clean rooms, and PTFE-fortified compounds for dry environments ensure lubrication performance without compromising product purity or safety.

Precision Equipment and Low-Friction Applications

Robotics, packaging machinery, precision instrumentation, and automated assembly lines require lubricants that minimize friction variation and provide consistent torque. Low-friction synthetic oils and precision greases enable accurate positioning, reduce energy consumption in servo motors, and extend the life of expensive motion control components.

Supporting Data & Validation: The Numbers Behind Smart Lubrication

The business case for strategic lubrication isn’t theoretical—it’s supported by decades of maintenance data and tribological research:

A comprehensive study by the Society of Tribologists and Lubrication Engineers found that proper lubrication practices reduce maintenance costs by 30-40% and energy costs by 10-12% in industrial facilities. When you factor in reduced downtime—which costs the average manufacturer $260,000 per hour according to industry research—the return on investment for premium lubricants becomes clear within months.

Consider the comparison between basic mineral oil and synthetic polyalphaolefin (PAO) lubricants in a typical gearbox application. While PAO-based oils may cost 2-3 times more upfront, they deliver 3-4 times longer drain intervals, reduce energy consumption by 3-5%, and extend component life by 50-100%. The total cost of ownership over a five-year period is 30-40% lower with synthetic lubricants, even accounting for higher purchase prices.

Thermal stability testing reveals why these performance differences matter. Mineral oils begin oxidizing rapidly above 180°F, forming sludge and varnish that accelerate wear. Advanced synthetic lubricants maintain stability up to 400°F, providing consistent protection across wider operating ranges and reducing the need for precision temperature control in process equipment.

Load-bearing capacity tests demonstrate similar advantages. Standard greases begin breaking down at 300-500 psi of contact stress, while EP-fortified synthetic greases maintain film strength beyond 2,000 psi. In heavy equipment applications, this difference determines whether you replace bearings annually or every five years.

The ChemPoint Advantage: Beyond Basic Lubricants

Most lubricant suppliers offer commodity mineral oils and standard greases. But what happens when your application demands more? When you need oxygen-safe formulations for compressed air systems? Chemical resistance for aggressive process environments? Extreme temperature stability for ovens or freezers? High-purity formulations for clean rooms?

ChemPoint provides access to specialized lubricant solutions that go beyond conventional offerings. Our portfolio includes:

- Oxygen-safe lubricants engineered to prevent ignition in high-pressure oxygen systems, protecting personnel and equipment in medical, aerospace, and industrial gas applications

- Chemically stable synthetic formulations that resist acids, bases, and solvents, maintaining lubrication performance in chemical processing environments where conventional lubricants degrade rapidly

- Extreme temperature lubricants spanning the range from -60°F to 500°F, ensuring equipment protection in thermal processing, cold storage, and other temperature-critical applications

- High-pressure specialty greases with extreme pressure additives that prevent wear in heavy equipment, mining machinery, and metalworking applications

- Low-friction precision oils for robotics, automation, and precision machinery requiring consistent torque and minimal friction variation

When your application extends beyond basic mineral oil or standard PAO formulations, ChemPoint connects you with the technical expertise and product selection to optimize your lubrication program. We help you identify the right solution for your specific operating conditions, reducing total cost of ownership while improving equipment reliability.

Start Optimizing Your Lubrication Strategy

The path to lower maintenance costs and improved equipment reliability begins with understanding your true lubrication requirements. Are you using commodity lubricants in specialty applications? Could consolidating your product portfolio reduce complexity and costs? Are energy losses from friction costing you thousands in electricity annually?Request a lubrication program assessment – Our technical team can evaluate your current lubricant usage and identify opportunities for cost reduction and performance improvement

Contact our technical sales team – Discuss your most challenging lubrication applications and explore solutions beyond standard offerings

Don’t let lubrication be an afterthought in your maintenance strategy. The difference between reactive maintenance and predictive reliability often comes down to using the right lubricant for the right application. Contact ChemPoint today to discover how advanced lubrication solutions can reduce your total cost of ownership while improving equipment performance and reliability.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - Canada