Select Your Region

MOLYKOTE® Lubricants: Optimizing Equipment Performance

Why Stribeck Curves Matter in Maintenance

In tribology, the Stribeck curve illustrates the relationship between friction and lubrication regimes: boundary, mixed, and hydrodynamic. Maintenance managers see this curve come to life every day—equipment failures often happen when systems operate too long in boundary or mixed lubrication regimes, where wear is accelerated. The goal is to shift as many operations as possible toward stable, low-friction regimes that extend equipment life and reduce breakdowns.

How MOLYKOTE® Extends Maintenance Cycles

MOLYKOTE® specialty lubricants are designed with Stribeck principles in mind. By lowering the coefficient of friction and creating protective films across different lubrication regimes, they help minimize wear during startup, protect surfaces under heavy load, and maintain performance in continuous operation.

Key benefits include:

- Reduced wear in boundary and mixed lubrication regimes

- Consistent film formation across varying loads and speeds

- Longer relubrication intervals that cut maintenance labor costs

- Higher overall plant efficiency through lower frictional losses

Broad Applications Across Industry

MOLYKOTE® lubricants are trusted across industries where uptime and reliability are critical. Typical applications include the following:

Bearings and gears that frequently cycle through start–stop conditions

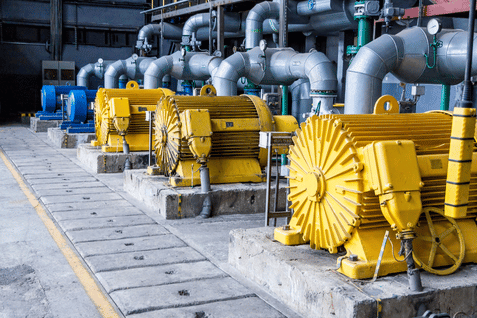

Pumps and mixers that must withstand high loads and continuous operation

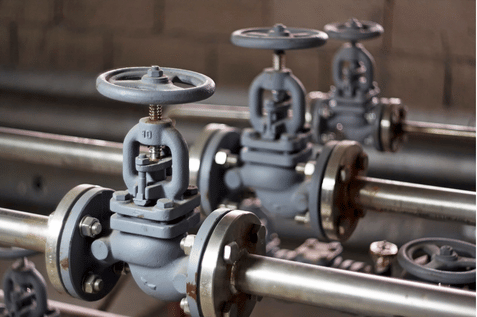

Valves, seals, and connectors exposed to harsh chemicals and temperature extremes

Conveyors and sliding mechanisms where friction control drives efficiency

Maintenance Strategy and Plant Reliability

Understanding where your equipment operates on the Stribeck curve provides valuable insight into lubrication strategy. By using MOLYKOTE® solutions, maintenance teams can proactively manage friction and wear across all regimes—reducing unplanned downtime, optimizing total cost of ownership, and ensuring consistent plant performance.

Next Steps

ChemPoint partners with DuPont to supply the full range of MOLYKOTE® lubricants. Whether you are troubleshooting wear problems or designing a lubrication program around tribology best practices, our team is here to help.

Explore the MOLYKOTE® product line or contact our experts today to see how MOLYKOTE® can support your maintenance strategy.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - Canada