Select Your Region

Triethyl Phosphate for Resins

Triethyl Phosphate

Eastman is a global leader in the manufacture of intermediates and chemicals for the polyester resin market. Polyester resins are widely used to produce a number of materials for automotive, residential, and recreational applications. Eastman triethyl phosphate (TEP) solvent is a high-purity grade of TEP utilized in polyester resin manufacturing for its ability to lower viscosity and improve flame resistance.Understanding Resin Viscosity

During resin production, viscosity is an important aspect as it influences the resin's ability to be processed. Liquid resins are polymerized or cross-linked to create a wide range of products. Fillers, pigments, and other additives are frequently added to the resin to reduce cost, improve appearance, or enhance the final performance of the finished product. However, these additives typically increase the resin's viscosity, which can make it difficult to process in spray or mold operations.To combat this issue, solvents or other chemical intermediates are used to reduce the solution viscosity. In laboratory studies of several resin systems, Eastman found that the addition of a small amount of triethyl phosphate (TEP) significantly lowered resin viscosity, thereby enhancing processability or allowing for higher additions of fillers and other additives.

Fiberglass Reinforced Plastics

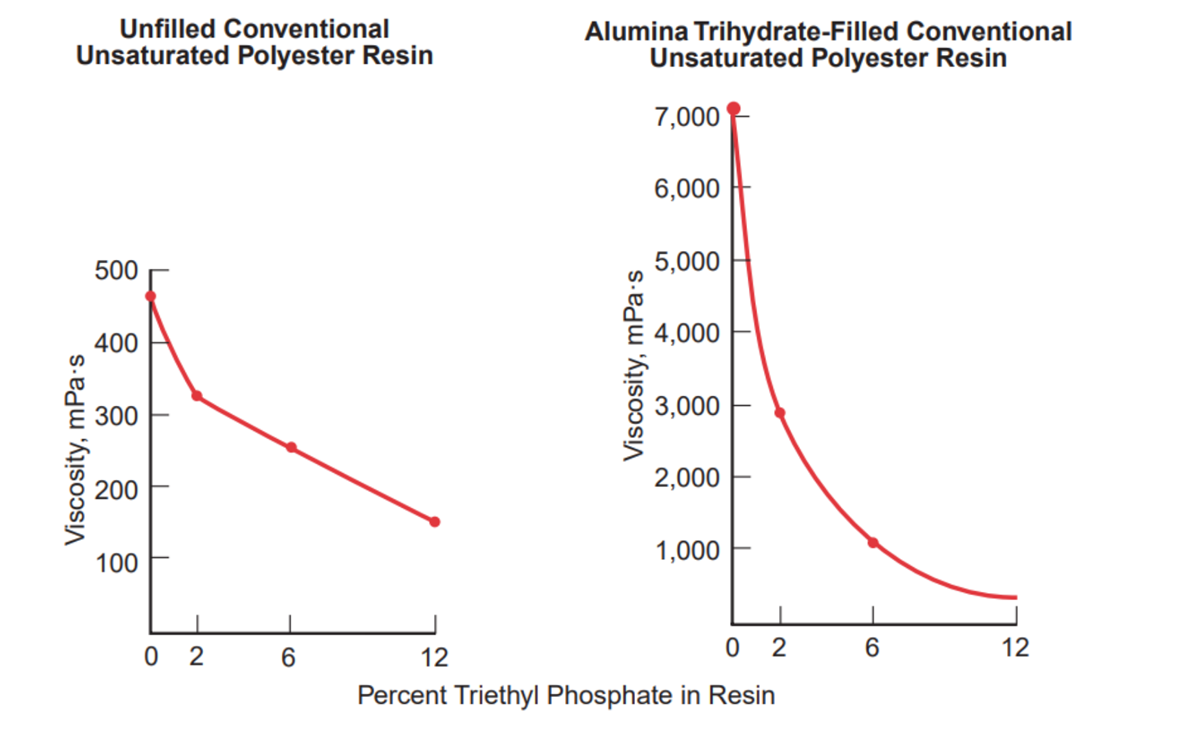

Fiberglass reinforced plastics typically require a certain degree of flame resistance. A halogenated intermediate is often incorporated in the polyester polymer structure to achieve the necessary flame resistance, or a cheaper method is to add alumina trihydrate as a filler. However, both solutions can significantly increase resin viscosity. Eastman TEP is an effective viscosity-reducing additive in both types of flame-resistant resin systems.The Effect on Resin Viscosity of Adding Eastman TEP to Filled and Unfilled Unsaturated Polyester Resins

Eastman found that their TEP was more effective than other common phosphorus-containing synergists in reducing the viscosity of polyester/styrene solutions. The addition of 3% TEP was enough to lower the viscosity of the original polyester–styrene solution from 1,150 to 720 mPa·s.

Urethane Foams

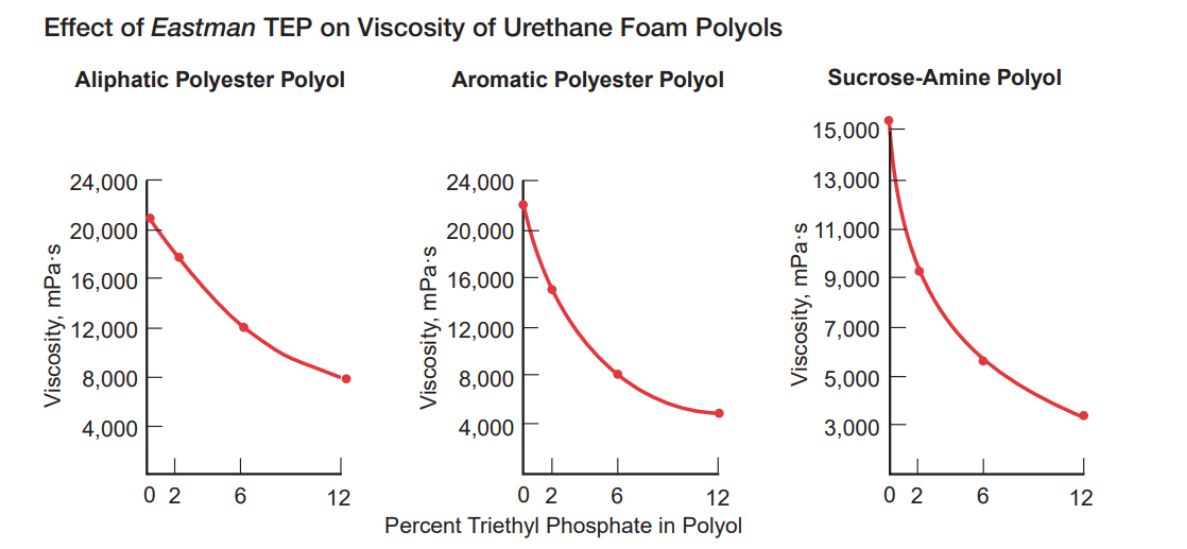

With the addition of 6% TEP, Eastman reduced the viscosity of the aliphatic polyester polyol used to produce flexible urethane by almost 50%. Aromatic polyester polyol and sucrose-amine polyol, which are used to make rigid urethane foam, experienced an even larger reduction.

Protective Coatings

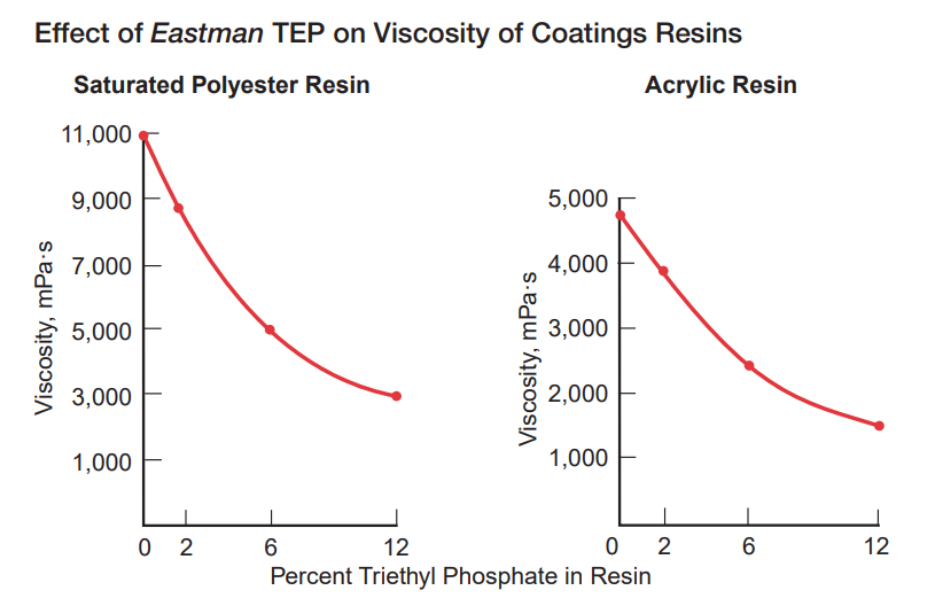

In the quest to lower organic solvent emissions from protective coatings, some manufacturers have chosen to use high-solids, low-viscosity formulations. Eastman TEP lowers the viscosity of acrylic and saturated polyester resins to manufacture high-solids protective coatings.

Synergies in Halogenated Resins

In addition to viscosity reduction, TEP also displays flame retardant properties in halogenated unsaturated polyesters due to the synergistic characteristics between phosphorus compounds and noncombustible halogenated gases. This combination slows down combustion when plastic decomposes at ignition temperatures.While antimony trioxide is the more widely used additive for improving fire resistance in halogenated plastics, the resulting opacity can be undesirable in certain applications. Antimony trioxide is more susceptible to settling out of the polyester–styrene material during storage. In applications that desire a clear end product, phosphate esters such as TEP, TPP, or TCP are often preferred for their higher compatibility with polyester–styrene solutions.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - Canada