Select Your Region

Protect Equipment During Holiday Shutdowns

Introduction

Holiday shutdowns are a valuable opportunity for maintenance teams—but they are also a period of high risk if systems are not properly prepared. When temperatures drop, idle equipment and process lines become vulnerable to freezing, corrosion, fluid breakdown, and unplanned downtime once operations resume. Add in year-end budget pressure and reduced staffing, and it is easy for critical preventive tasks to slip through the cracks.

This article outlines practical, field-tested steps to help maintenance and plant managers protect their facilities during winter shutdowns—minimizing startup issues, preserving equipment life, and ensuring a smooth restart in January.

1. Develop a Comprehensive Shutdown Plan

Preparation should begin well before the final production run. A structured plan ensures that every asset, fluid, and subsystem is properly secured.

Key actions to include the following:

- Asset Prioritization: Identify critical systems that must remain operational (e.g., temperature-sensitive or safety-critical equipment) and those that can be safely shut down.

- Responsibility Matrix: Assign clear ownership for each task, including valve closures, drain downs, electrical isolation, and inspections.

- Shutdown Sequencing: Define the order for powering down production lines, utilities, and auxiliary systems to avoid pressure spikes or trapped fluids.

- Documentation: Record all valve positions, lockout and tagout actions, and system conditions for reference during restart.

Pro tip: Facilities that perform mock shutdown drills in November report significantly fewer issues during the real thing.

2. Protect Fluids, Lines, and Tanks from Cold Damage

Even a few hours of freezing temperatures can cause extensive damage to heat exchangers, cooling loops, and storage tanks.

Consider these best practices:

Drain or Displace Water: Water left in idle systems expands as it freezes, leading to burst lines or cracked fittings. Drain nonessential circuits or circulate with a heat transfer fluid rated for local ambient conditions.

Insulate and Heat Trace: Critical lines, pumps, and valves should have insulation and functional heat tracing tested in advance. Infrared scans can quickly identify cold spots or failed heat tapes.

Maintain Fluid Quality: Check the pH, inhibitor levels, and the concentration of any recirculating system fluids (glycols, coolants, or brines). Adjust before shutdown to avoid corrosion or reduced freeze protection.

Tank Storage: Keep drums and totes in climate-controlled spaces. Temperature swings cause condensation and microbial growth in stored fluids.

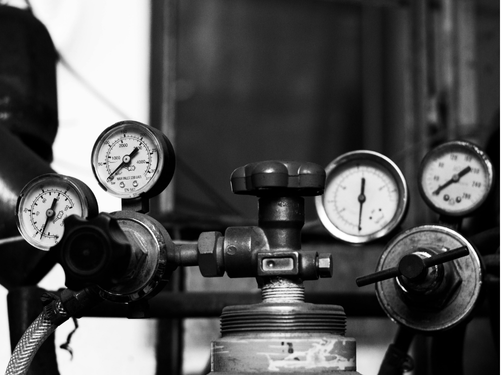

3. Prevent Corrosion and Mechanical Seizure

Idle equipment can deteriorate surprisingly fast when exposed to condensation, oxidation, or vibration.

We would recommend the following steps:

- Lubricate Moving Parts: Apply fresh grease or oil to bearings, gears, and seals to create a protective barrier. Focus on motors, conveyors, valves, and actuators.

- Seal Off Air Ingress: Moisture in compressed air or hydraulic lines can lead to internal rust. Drain receivers and use desiccant breathers where applicable.

- Protect Metal Surfaces: Use vapor-phase inhibitors or light protective coatings on exposed components, flanges, and spare parts.

- Vibration Isolation: For long idle periods, secure or support rotating equipment to prevent bearing wear from micro-movements.

4. Electrical and Control Systems Care

Electrical components are often overlooked during shutdown, but temperature and humidity swings can be damaging.

Here are some of our best practices:

- De-energize nonessential circuits to prevent parasitic loads and reduce fire risk.

- Inspect MCCs and panels for condensation or corrosion signs. If heaters or dehumidifiers are installed, ensure they are operational.

- Back up control system data before shutdown in case of unexpected power loss or system resets.

- Label and photograph settings on variable frequency drives and controllers for easier restart verification.

5. Use the Downtime for Preventive and Predictive Maintenance

A holiday shutdown is not just about protection—it is an opportunity to get ahead on maintenance tasks that are hard to schedule during production.

Consider using the downtime to:

- Replace worn hoses, gaskets, and filters that might cause leaks or contamination on restart

- Perform vibration and oil analysis on critical motors and pumps

- Clean heat exchangers, condensers, and coils to improve efficiency

- Calibrate sensors and inspect control valves for full travel and response

- Conduct safety checks on emergency systems, lighting, and fire suppression

- Facilities that treat shutdowns as maintenance investments often report reduced downtime and energy costs over the following year.

6. Create a Documented Restart Checklist

Restarting a facility can introduce its own risks if done haphazardly. A restart checklist ensures systems come online safely and predictably.

Consider including:

- Visual inspections of all fluid levels, seals, and valves

- Gradual repressurization of lines and vessels

- Controlled heating and circulation of thermal systems before introducing full load

- Verification of all safety interlocks, sensors, and alarms

- Review of any anomalies logged during shutdown

- Documenting restart results also helps build institutional knowledge for future years.

7. Leverage Expert Support for Winterization and Maintenance Planning

Every facility faces unique conditions; ambient temperature ranges, system age, fluid chemistry, and staffing models all affect the ideal shutdown plan. ChemPoint’s MRO specialists can help assess your current procedures, analyze heat transfer or lubrication systems, and identify opportunities to reduce risk and cost.

Whether you need help testing system fluids, selecting maintenance materials for extreme cold, or building a preventive maintenance calendar for 2026, our experts can support you every step of the way.

Want to Learn More?

Ready to prepare your facility for a worry-free restart? Contact ChemPoint’s MRO team to schedule a shutdown planning consultation or speak with a technical expert about best practices for your operation.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - Canada