Select Your Region

DOWFROST™ LC for Colocation Data Center Liquid Cooling

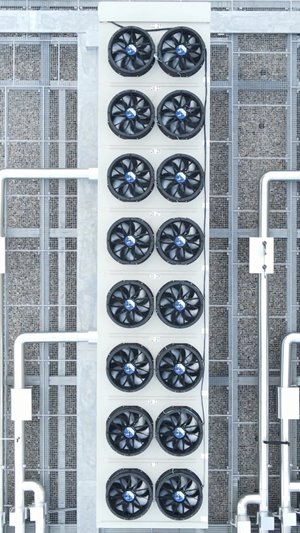

Colocation facilities are under increasing pressure as tenants demand higher rack densities, driven by AI, HPC, and GPU-intensive workloads. With racks pushing 30–50 kW and beyond, traditional air cooling alone cannot deliver the uptime and efficiency that colocations promise in their SLAs.

Production engineers are now tasked with implementing scalable, reliable liquid cooling strategies that protect infrastructure, satisfy diverse tenant needs, and control operating costs.

Core Benefits for Colocation Facilities

- Scalable Performance – DOWFROST™ LC enables glycol-based secondary loop systems to adapt to a wide range of rack densities, from traditional enterprise servers to next-generation AI clusters.

- Operational Reliability – Proprietary corrosion inhibitors extend equipment life and reduce risk in shared infrastructure.

- Tenant Safety & Compliance – The low-toxicity, FDA-cleared formulation reduces liability in multiclient environments.

- Predictable Cost Control – Incremental deployment and compatibility with existing equipment make DOWFROST™ LC far less disruptive than immersion fluids.

- Trusted Supply Partner – DOWFROST™ LC is backed by Dow’s product innovation and ChemPoint’s distribution expertise, ensuring secure supply and technical support.

Applications & Use Cases

Cold plates and rear door heat exchangers for high-density tenant racks

Secondary loop systems separating racks from facility chillers

Hybrid environments that combine air and liquid cooling

AI and HPC service tiers designed around liquid-ready infrastructure

Supporting Data & Industry Trends

- Air vs. Liquid Cooling – Air remains viable for lower-density racks, but studies show racks above 20–30 kW require liquid cooling to remain efficient.

- Colocation Adoption Curve – AI tenants are driving operators to accelerate liquid deployments. Glycol-based systems like DOWFROST™ LC offer a smooth transition without requiring tenants to abandon existing hardware designs.

- Performance Validation – DOWFROST™ LC demonstrates stable thermal performance, corrosion protection, and long service life across cycling conditions typical in data center environments.

Why DOWFROST™ LC Leads the Way

When colocation providers evaluate their cooling strategies, the choice often comes down to water, glycol, or immersion fluids. DOWFROST™ LC stands out as the most practical, scalable option—delivering the efficiency of liquid cooling while avoiding the operational disruption of immersion systems. Plus, with DOWFROST™ LC, colocators gain a branded, globally trusted solution that keeps them ahead of tenant demand and positions them as liquid-ready partners in a rapidly changing industry.Future-proof your colocation facility with DOWFROST™ LC. Contact ChemPoint today to learn how our team can support implementation, ensure supply continuity, and help you deliver differentiated, SLA-backed service for your tenants.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - Mexico