Select Your Region

How to Use POLYOX™ & UCARFLOC™ Flocculation Sample Guide

POLYOX™ and UCARFLOC™ are effective flocculants for clays, silica, silt, paper fines, and more. They can help reduce the total amount of flocculant needed through their high efficacy. Often, only a few ppm is required, and adding in excess results in failure. Determining the optimal concentration is critical for flocculant performance and cost considerations.

POLYOX™ and UCARFLOC™ can be mixed directly into turbid wastewater as a powder or mixed into potable water to create a stock solution.

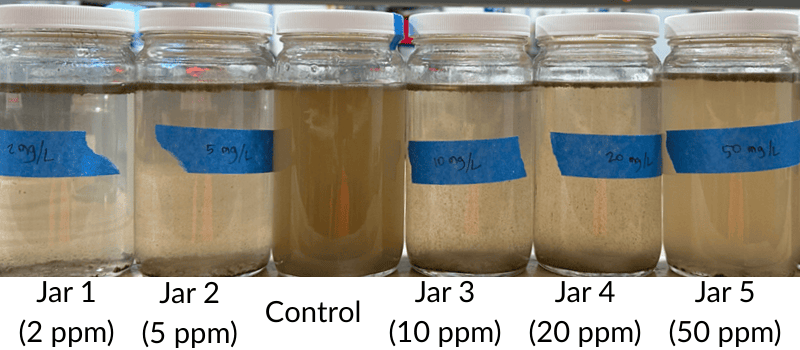

Since the concentrations needed for benchtop testing are often very low, ranging from 1–100 ppm, measuring the appropriate mass of POLYOX™ and UCARFLOC™ for a 1-liter jar test may be smaller than the sensitivity of scales present in most labs. Presented below is a ladder study using 1-liter jars with stock solutions to determine the optimal concentration for sedimentation using UCARFLOC™ 309. As observed, the jar containing 2 ppm UCARFLOC™ 309 provided the best sedimentation performance.

Jar Test for Sedimentation

POLYOX™ and UCARFLOC™ can be mixed directly into turbid wastewater as a powder or mixed into potable water to create a stock solution.

Since the concentrations needed for benchtop testing are often very low, ranging from 1–100 ppm, measuring the appropriate mass of POLYOX™ and UCARFLOC™ for a 1-liter jar test may be smaller than the sensitivity of scales present in most labs. Presented below is a ladder study using 1-liter jars with stock solutions to determine the optimal concentration for sedimentation using UCARFLOC™ 309. As observed, the jar containing 2 ppm UCARFLOC™ 309 provided the best sedimentation performance.

Example Jar Test Parameters of UCARFLOC™ Per Unit of Wastewater

Jar

|

Parts per million

|

Stock solution*/liter (mL)

|

mg/liter

|

mg/gallon

|

ounces/gallon

|

|---|---|---|---|---|---|

1

|

2

|

2

|

2

|

8

|

0.0002

|

2

|

5

|

5

|

5

|

19

|

0.0007

|

3

|

10

|

10

|

10

|

38

|

0.0013

|

4

|

20

|

20

|

20

|

76

|

0.0027

|

5

|

50

|

50

|

50

|

189

|

0.0067

|

Control

|

0

|

0

|

0

|

0

|

0.0000

|

*1 g/L stock solution of UCARFLOC™ in water

It is recommended to use an overhead mixer as shown below. For ease of measurement in jar testing, it is recommended to make a stock solution of 1 g/L to make the conversions to ppm easier (see the table above).

Mixing Stock Solutions

It is recommended to use an overhead mixer as shown below. For ease of measurement in jar testing, it is recommended to make a stock solution of 1 g/L to make the conversions to ppm easier (see the table above).

1. Start mixing clean water at ~800 RPM with a medium–low shear mixer.

1a. (Optional) Disperse the desired amount of powder into IPA or glycerin.

This will reduce the amount of time required for mixing.

This will reduce the amount of time required for mixing.

2. Slowly sprinkle POLYOX™/UCARFLOC™ into the vortex.

Ideally, the desired effect is to have the maximum amount of distance between each particle at the moment of wetting.

Ideally, the desired effect is to have the maximum amount of distance between each particle at the moment of wetting.

3. Once all the powder/dispersion has been added, immediately slow the mixing down to ~60 RPM.

If globules are present, do not compensate by increasing RPM; this will cause shear degradation, resulting in a less effective flocculant. It is important to give the mixture time to swell and dissolve until the resulting solution is optically clear and uniform.

If globules are present, do not compensate by increasing RPM; this will cause shear degradation, resulting in a less effective flocculant. It is important to give the mixture time to swell and dissolve until the resulting solution is optically clear and uniform.

Note: Stock solutions will slowly oxidize in water and should be used within days to weeks of mixing.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - Mexico