Select Your Region

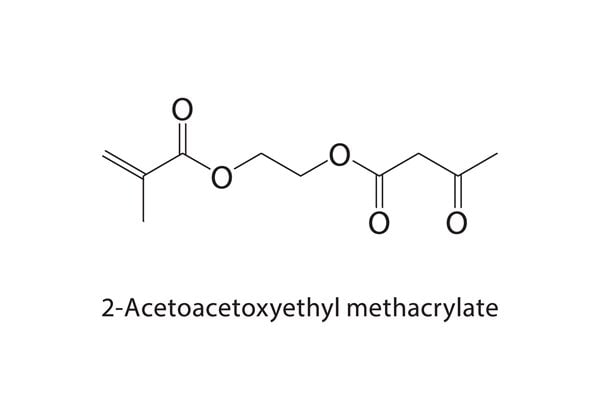

What Is Acetoacetoxyethyl Methacrylate (AAEMA)?

Arxada Diketene Derivatives

Arxada is a leading manufacturer of specialty chemical solutions for a wide range of markets. The diketene derivatives, including acetoacetoxyethyl methacrylate, play an important role in resin production for paints and coatings.Product Overview

2-Acetoacetoxyethyl methacrylate (CAS No. 21282-97-3), also known as AAEMA or AAEM, is a specialty acrylic monomer used as an intermediate chemical to produce high-performance resins and acrylic emulsions. AAEMA readily polymerizes with other acrylic monomers, and the chemical structure allows for cross-linking at room temperature, enabling the manufacture of interesting, innovative polymers. Physically, the product is an odorless, clear, light-yellow liquid that is soluble in water and miscible in organic solvents.

Safety Profile

According to US Regulation 29 CFR 1910.1200 and the Canadian HPA, AAEMA is not classified as a hazardous substance or mixture. Like other acrylic monomers, the primary concerns include eye and skin irritation, inhalation, flammability, and spontaneous exothermic polymerization. The chemical should be stored in a tightly closed container in a well-ventilated space and not exposed to heat or direct sunlight. To prevent spontaneous polymerization, avoid contact with initiators, such as amines, acids, and oxidizing agents. Use equipment that is clean and free from contaminants. As with any monomer, handle AAEMA with proper hand, eye, and body protection and in accordance with good industrial hygiene and safety practice. We can provide a GHS-compliant SDS to ensure you have sufficient understanding of the EH&S information and safety product handling procedures.What Are the Benefits of AAEMA?

Self-Cross-Linking Technology

AAEMA has an active methylene group and a ketone carbonyl group that can self-cross-link at room temperature. This chemistry allows for various cross-linking pathways, providing formulators the ability to create new polymer systems and develop high-performance coatings. The methylene group actively reacts with melamines, isocyanates, and aldehydes, while the ketone carbonyl group can self-cross-link with enamines. The carbonyl group can also be chelated with metal ions, such as tin, aluminum, zinc, and copper, for improved adhesion and corrosion resistance in metal coating applications.Low Viscosity

Because of the long, bulky side chain that increases chain separation between polymer chains, AAEMA reduces the viscosity of acrylic emulsions. This is particularly beneficial for high-solids, low-VOC coatings that require lower viscosity resins.Enhanced Film Properties

By cross-linking with other polymers, AAEMA can enhance the mechanical properties of the finished coating, including durability, impact strength, stain and corrosion resistance, and adhesion performance.Common Applications

Acrylic resins produced with AAEMA are used in a number of applications, including paints, adhesives, sealants, architectural and industrial coatings, water-repellent and marine coatings, and inks and colorants.

Paints

Adhesives

Metal Coatings

Gel coats

Colorants

Inks

Arxada AAEMA

Arxada AAEMA is a high-purity grade of acetoacetoxyethyl methacrylate with an assay of 95% or higher, manufactured to meet strict regulatory standards. Arxada and ChemPoint are committed to our customers' success. Call today to speak with a technical specialist and find out if AAEMA is the right solution for you!

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - Canada