Kemamide® Amides

Select Your Region

Kemamide® Amides

Enhanced compatibility

Metallic Stearates

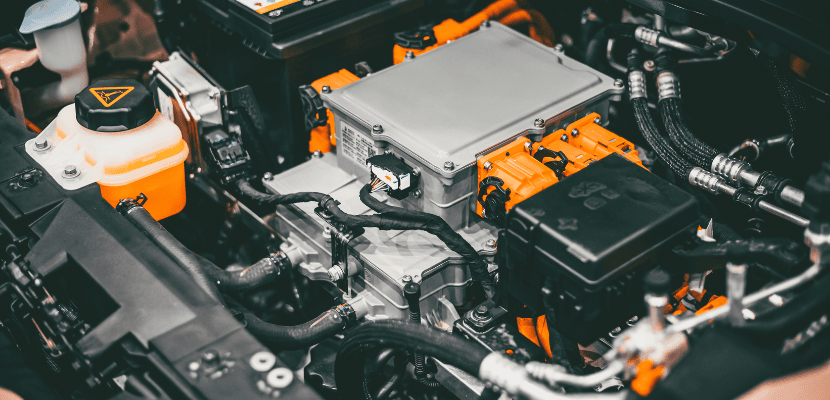

Efficiency

The role of metallic stearates in improving efficiency is multifaceted. As internal lubricants, they reduce friction and wear in polymer-based components, similar to Kemamide® amides. Additionally, they enhance the thermal stability of polymers, which is crucial for components exposed to the varying thermal conditions in EVs. This improved stability ensures that components retain their properties over the vehicle's lifespan, thus maintaining efficiency.

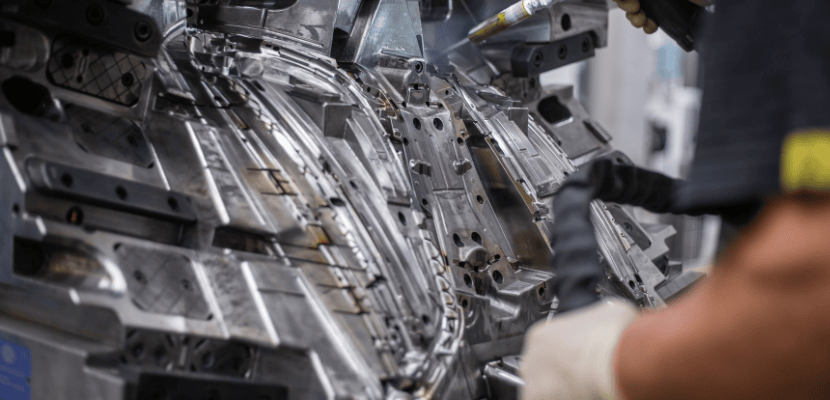

Processing

Metallic stearates are widely recognized for their ability to enhance the processability of polymers. They serve as effective lubricants, reducing the melt viscosity and improving the flow characteristics of polymer compounds. This results in smoother extrusion and molding processes, higher throughput, and reduced energy consumption during manufacturing. The use of metallic stearates can also lead to improved surface finishes on molded parts, reducing the need for additional postprocessing steps.

Fatty Acids

Industrene® B and Hystrene® 9016 are specific types of fatty acids used extensively in the plastic and rubber industries. Their unique properties contribute significantly to the improvement of electric vehicle design by enhancing material performance, processability, and overall efficiency. This leads to the production of more durable and cost-effective components, which are essential for advancing EV technology.

Lubrication

In rubber formulations, Industrene® B acts as a processing aid, improving the mixing and dispersion of fillers and additives. This leads to more uniform and consistent material properties, essential for high-performance EV components such as tires, seals, and gaskets.

Stabilizer

Industrene® B also acts as a stabilizer, protecting materials from thermal and oxidative degradation. This is particularly important for EV components exposed to varying temperatures and environmental conditions, ensuring long-term durability and performance.

Durability and Efficiency

The lubrication and processing aid characteristics of Industrene® B and Hystrene® 9016 improve the flow properties and processability of materials during manufacturing. This results in smoother production processes, higher throughput, and reduced energy consumption, making EV component manufacturing more cost-effective and efficient.

Processability

The lubrication and processing aid characteristics of Industrene® B and Hystrene® 9016 improve the flow properties and processability of materials during manufacturing. This results in smoother production processes, higher throughput, and reduced energy consumption, making EV component manufacturing more cost-effective and efficient.

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - Canada