Papermaking and Retention Aids

During the first steps of papermaking, pulp slurries are created, sent into a head box, and dispersed onto machine wires to begin the drying process and form a paper web. In this last step, approximately 60% of the water in the paper slurry must be removed, and retention aids play a significant role in determining paper quality and manufacturing efficiency. UCARFLOC™ is a line of high-viscosity polyethylene oxide retention aids developed for the papermaking industry that work at relatively low concentrations to provide the following benefits:

-

Increased first-pass retention of pulp, fiber, and commonly used fillers like kaolin clay and TiO₂

-

Creation of drainage effluent that is easier to filter and recycle

-

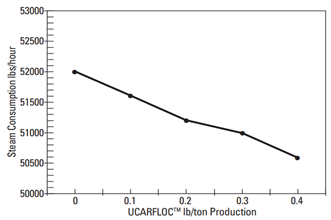

Reduced energy consumption required for steam roller drying

-

Better paper consistency and effective removal of pitch

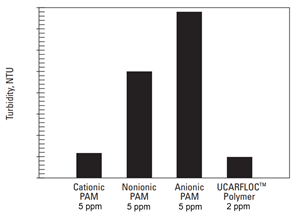

These benefits stem from the fact that UCARFLOC™ retention aids are adept at flocculating fine particles in the pulp slurry. For more information on the mechanism in which polymers like UCARFLOC™ perform flocculation, check out this article.

How UCARFLOC™ Retention Aids Improve Modern Papermaking Processes

Generally, maximizing the retention of pulp, fines, and fillers is key to the initial papermaking process because it leads to increased paper web strength, prevents visual and physical defects, and creates process water that is easier to filter and reuse. In the past several years, paper mills have also adopted new trends that necessitate highly functional retention aids to offset challenges.

| Papermaking Trend |

Resulting Challenge |

Functionality of UCARFLOC™ |

Benefit of UCARFLOC™ |

| Higher cost of pulp and increased usage of fillers, recycled fiber, and high-yield pulp |

More particulate must be retained from drainage |

Flocculates high concentrations of fiber, fines, fillers, and pulp |

Improves utilization of pulp, fillers, and fiber invested |

| Faster machine line speeds |

Less time to retain particulate in drainage |

Efficiently flocculates suspensions of paper particulate |

Enables faster line speeds while maintaining paper quality |

| Increased water conservation by recycling effluent water |

More pulp, fillers, fiber, and fines in recycled water |

Highly effective at removing pulp, fiber, fillers, and fines from water |

Reduces water costs and improves filtration processes |

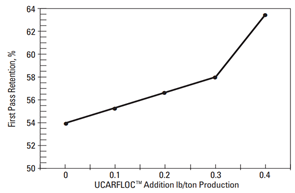

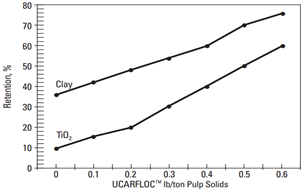

Below are data illustrating how well UCARFLOC™ increases first-pass retention of fillers like clay and titanium oxide. The paper furnishes used in this study contained 75% refined mechanical pulp and 25% semibleached kraft pulp. As a result of this increased retention, finished paper sheets had increased opacity and brightness, owing to the higher number of fines and TiO₂ retained. Other commonly used fillers, such as sodium aluminum silicate and calcined clay, have also been retained effectively using UCARFLOC™ retention aids and a combination of phenolic resin enhancers.

| Effect of UCARFLOC™ on First-Pass Retention |

Retention of Fillers using UCARFLOC™ |