Select Your Region

METHOCEL™ for Better Barrier Coating Formulations

Nowadays, it is common to see paper being used as a material of construction for food packaging, such as plates, trays, cups, and wrappers. As food packaging manufacturers move toward using paper over less sustainable materials, such as plastic, they have encountered challenges in preventing the migration of grease, oil, and other contaminants into food. This is because a large portion of paper packaging is made from recycled content, which contains impurities that are not removed during the recycling process. Thus, solutions such as barrier coatings for paper are being developed to prevent such contamination, which can occur even if there are plastic materials between the paper and food.

What Is a Barrier Coating?

Barrier coatings prevent the passage of chemicals, heat, moisture, gas, or other conditions that degrade the quality of products. In the context of paper food packaging, the primary functions of barrier coatings are to prevent grease and oil from migrating into the paper, reduce moisture vapor transmission rate, and stop the migration of contaminants into food.

METHOCEL™ for Barrier Coatings

Formulators of barrier coatings used in paper packaging applications prioritize ingredients that complement the sustainability of the paper substrates to which they are applied. METHOCEL™ is a cellulose-based polymer that offers several features that make it ideal for use as a binder in paper packaging barrier coatings, as listed below.

- Derived from natural wood and cotton linters with a biogenic carbon content of 56%–77%

- Easily forms durable films with good oil, grease, and contaminant barrier properties

- Unique thermal gelation property enables easy recovery in recycling processes

- Not considered a microplastic

Film Formation and Ease of Recycling

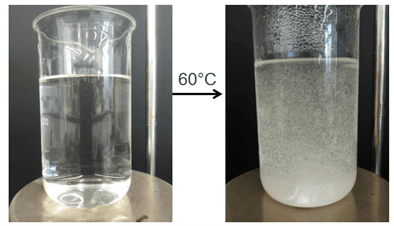

METHOCEL™ is an exceptional film former that forms clear, tough, and flexible films that perform as excellent barriers. It may be used to form films in water-based formulations or, since some grades behave as thermoplastic polymers, may be cast or extruded. Compared to other binders used on the market for barrier coatings, METHOCEL™ has a unique property known as thermal gelation, which converts it into an insoluble gel or flocculates at or above the thermal gelation temperature threshold. When paper products coated with barrier coatings containing METHOCEL™ are placed in recycling streams, METHOCEL™ solids can be easily separated using liquid filtration processes. Below, an image of a solution of METHOCEL™ is shown to form precipitated solids when heated.

Barrier Performance

Over time, contaminants such as mineral oil saturated hydrocarbons (MOSH), mineral oil aromatic hydrocarbons (MOAH), photoinitiators, and phthalates end up within recycled paper as a part of the recycling process. These contaminants originate from sources ranging from the inks used to print on the previous paper substrate to the chemicals used in the recycling process. METHOCEL™ has been evaluated to show effective barrier properties against these impurities, which can evaporate and migrate into food over time. A study was made using recycled cardboard impregnated with common contaminants, where several coating formulations using METHOCEL™ or a blend of METHOCEL™ and propylene glycol were prepared. These were applied in a 7µm dry thickness to the recycled cardboard using a doctor blade, where the measurement for the migration of contaminants through the coating was performed after the coating was fully cured. Below are the results.Formulation

|

METHOCEL™ E3/PG

|

METHOCEL™ E3/PG

|

METHOCEL™ K3/PG

|

METHOCEL™ K3/PG

|

METHOCEL™ E3

|

METHOCEL™ K3

|

|---|---|---|---|---|---|---|

W/W ratio of METHOCEL™ to solvent

|

85.7:14.3

|

73:27

|

82.6:17.4

|

73:27

|

100:0

|

100:0

|

W/W concentration of METHOCEL™ to solvent

|

35

|

37

|

29

|

35

|

30

|

25

|

Migration of n-hexadecane (%)

|

4.5

|

2.8

|

8.5

|

11.6

|

11.7

|

4.1

|

Migration of N-eicosane (%)

|

0.1

|

0.7

|

1.7

|

1.7

|

2.7

|

0.8

|

Migration of biphenyl (%)

|

2.8

|

1.6

|

3.9

|

6.8

|

6.6

|

1.4

|

Migration of naphthalene (%)

|

2.9

|

0.9

|

8.9

|

12.7

|

9.1

|

1.8

|

Migration of 1-phenyldodecane

|

1.4

|

1.0

|

2.6

|

3.4

|

1.8

|

1.0

|

Migration of methylbenzophenone (%)

|

0.0

|

0.5

|

0.0

|

2.7

|

0.0

|

0.0

|

Migration of dicyclohexyl phthalate (%)

|

0.0

|

0.0

|

0.0

|

0.0

|

0.0

|

0.0

|

The results above represent the percentage of migration for the listed contaminants, with 100% migration being the control. All variants of the METHOCEL™ barrier coating formulation drastically minimized the migration of contaminants to the reverse side of the recycled cardboard. Notably, all formulations also completely prevented the migration of dicyclohexyl phthalate, a substance of very high concern in the EU.

It should be noted that while this article focuses mainly on barrier coating results using paper substrates, plastic packaging materials, such as PE films, also do not inherently provide a barrier to the contaminants examined. Therefore, barrier coatings containing METHOCEL™ may also be a good option for plastic packaging.

Summary

Barrier coatings on recycled paper and cardboard are essential to prevent the penetration of oil, grease, and contaminants into food, even if there are plastic materials separating the paper and food. METHOCEL™ is an ideal binder for barrier coating formulations due to its plant-based nature that resists the migration of contaminants and facilitates easy recycling. Click below to request a sample of METHOCEL™, and one of our product experts will be happy to assist you in formulation.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - Mexico