La infraestructura abarca toda la red de transporte, comunicaciones, redes energéticas y logística de los servicios de carga. Recientemente, Estados Unidos aprobó uno de los acuerdos de infraestructura más importantes para mejorar la competitividad de su infraestructura nacional. La magnitud de la Ley Bipartidista de Infraestructura puede brindar una enorme oportunidad de crecimiento para los fabricantes de polímeros con sede en Estados Unidos.

Coatings

Infrastructure coatings are required to protect pipes and tanks from the effects of water or chemical exposure. Coatings can lengthen the lifespan and mechanical properties of the equipment and allow for delayed corrosion. SI Group has a range of solutions for industrial coatings, from phenolic resins to antioxidants to UV stabilizers, that not only help maintain structural integrity but also increase the equipment’s functional life.

Powder Coatings Solutions

| Grade |

Chemistry |

Summary |

| LOWILITE™ 28 |

Benzotriazole |

General-purpose benzotriazole with low base color |

| LOWINOX™ 44B25 |

Phenolic |

High-activity, nondiscoloring phenolic antioxidant with chemical and hydrolytic stability for polyester resins |

| ANOX™ PP18 |

Hindered Phenolic |

General-purpose phenolic antioxidant with good solubility |

Liquid Coatings Solutions

| Grade |

Chemistry |

Summary |

| ANOX™ 1315 |

Phenolic |

Low-viscosity liquid phenolic antioxidant with good solubility in nonpolar substrates |

| LOWINOX™ GP45 |

Phenolic |

High molecular weight phenolic antioxidant with very low volatility and excellent resistance to extraction |

| LOWILITE™ 55 |

Benzotriazole |

UV light absorber that offers a high degree of photostability |

Alambres y cables

Los cables y alambres tienen una amplia gama de aplicaciones en infraestructura, desde paneles solares hasta turbinas eólicas, banda ancha y telecomunicaciones. Los productos de aislamiento y revestimiento fabricados por extrusión pueden experimentar un proceso de degradación denominado arborización hídrica al exponerse a la humedad o a la tensión eléctrica. El aislamiento de cables de polietileno se beneficia del antioxidante excepcionalmente eficaz

ETHANOX™ 330 , que protege contra la degradación por exposición a altas temperaturas.

Estaciones de carga para vehículos eléctricos

Las estaciones de carga de vehículos eléctricos requieren componentes de cables y alambres. Los materiales poliméricos, como las poliamidas, también experimentarán un crecimiento significativo para maximizar la eficiencia del cargador de vehículos eléctricos. Ya sea que se trate de la electrónica de potencia interna o de cargadores de vehículos eléctricos, las bombas, los colectores, las tuberías del sistema y los conectores deben garantizar durabilidad y seguridad. La gestión térmica de los requisitos de alto voltaje y la protección UV se logran mediante la incorporación de antioxidantes y estabilizadores de luz.

GRADO DESTACADO

ETHANOX® 330 para aplicaciones de tuberías de HDPE

El antioxidante ETHANOX™ 330 presenta un rendimiento superior al de los antioxidantes típicos de alto peso molecular en el control de la degradación de polímeros de poliolefina durante el procesamiento. La hidrólisis de los grupos éster de antioxidantes equivalentes competitivos en agua desionizada y la migración resultante desde películas de PP se demostraron mediante HPLC. ETHANOX™ 330 no presenta estos enlaces éster, lo que le confiere una resistencia superior a la hidrólisis.

¿Por qué elegir? ETHANOX® 330 ?- Polvo cristalino de alto peso molecular

- Proporciona estabilidad a largo plazo

- Estabilizador de procesamiento superior

- Biológicamente inerte

- Extraibilidad extremadamente baja

- Buenos beneficios en uso relleno y retardante de llama.

- No imparte olor ni color.

- Eléctricamente neutro

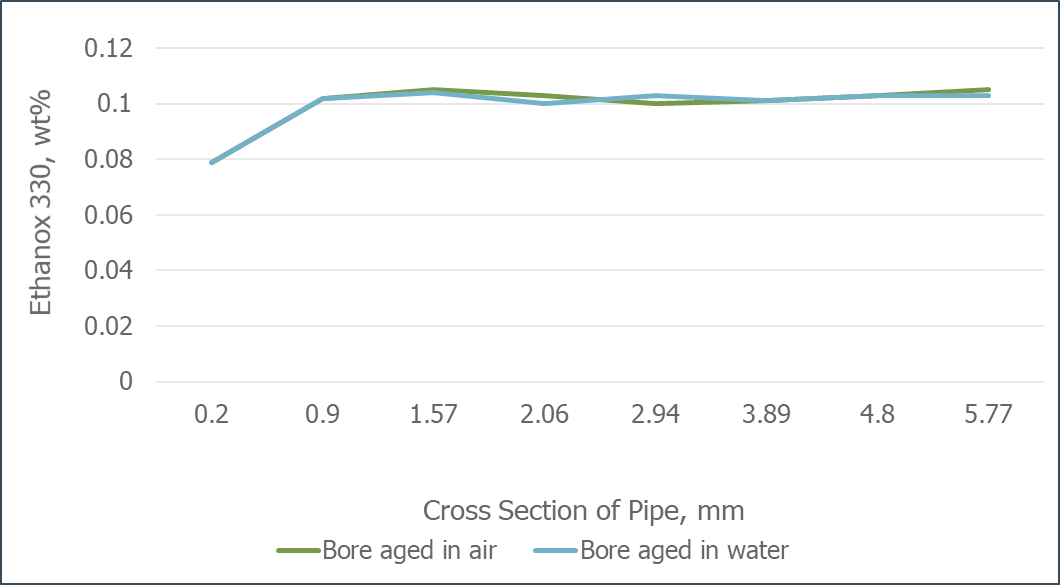

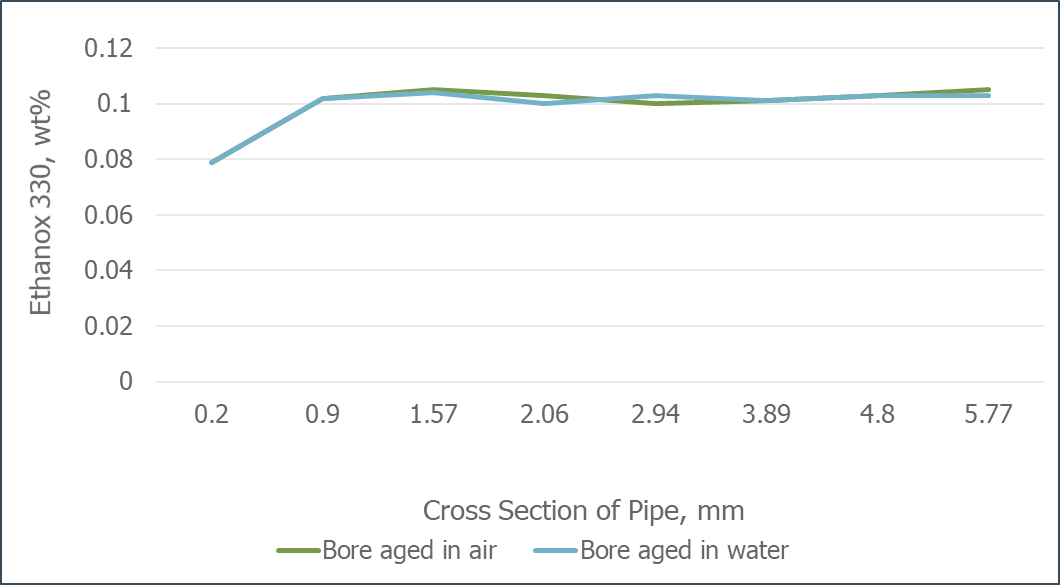

Resistencia a la extracción de ETHANOX® 330 en tuberías de HDPE

A través de la prueba de resistencia a la extracción, no hay pérdida de ETHANOX™ 330.

Tubo extruido (diámetro exterior = 63 mm) que contiene 0,1 % de radiomarcado

ETHANOX® 330, envejecido a 60°C durante 3 meses

Hable hoy con un especialista para saber qué aditivo estabilizador de polímeros de SI Group puede funcionar mejor para su formulación.