Select Your Region

EPOLENE® Oxidized Polyethylene Wax

What Is Oxidized Polyethylene Wax?

Wax additives have been used for decades to improve the performance and surface of chemical formulations such as coatings and inks. As water-based formulations become more prevalent in modern times due to environmental and health reasons, oxidized polyethylene waxes provide great utility. Oxidized polyethylene waxes are typically low-density polyethylene polymers that have been chemically modified to increase polarity, enabling them to be emulsified in water.

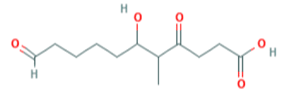

A simplified chemical structure of this wax is below, exhibiting possible hydroxyl, carbonyl, carboxyl, and aldehyde groups that increase polarity. Other types of waxes, such as paraffin and carnauba wax, contain few to no polar groups that enable them to be used in water-based formulations.

How Is Oxidized Polyethylene Wax Used?

Oxidized polyethylene wax is used in applications ranging from inks to plastic compounds to floor and textile finishes. In these applications, it is typically used in small weight percentages and helps provide one or more of the following properties.- Improved gloss

- Increased abrasion resistance

- Antiblocking

- Surface lubricity

- Water repellency

- Enhanced emulsion formulation stability

- Better adhesion to various substrates

EPOLENE® Emulsifiable Polyethylene Wax

Westlake manufactures EPOLENE® E-type polyethylene waxes with various options in terms of density, hardness, softening point, and molecular weight. Each E-type wax is produced in Longview, Texas, and is designed to provide suitability for specific emulsion or plastic compounding applications.Grade

|

Recommended Applications

|

Key Characteristics

|

|---|---|---|

Floor finishes

|

|

|

Fabric and textile finishes

|

|

|

Internal PVC lubricant

|

|

|

Agricultural product coatings

|

|

|

Floor finishes

Inks Paints |

|

|

Floor finishes

|

|

|

Fabric and textile finishes

|

|

|

Agricultural product coatings

|

|

|

Floor polishes

|

|

|

Plastic compatibilization

|

|

|

Floor polishes

|

|

|

Plastic compatibilization

|

|

|

Internal PVC lubricant

|

|

ChemPoint helps with grade selection, sampling, and pricing on EPOLENE® oxidized waxes. We can also help you find equivalent EPOLENE® grades for other polyethylene wax brands. Click below to get in touch with one of our technical experts to start working with EPOLENE®.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - Mexico