Select Your Region

Scogin® Alginates for Sustainable Packaging

|

Sustainable Packaging MaterialsRecently, a greater focus on sustainability within governmental regulations, consumer consciousness, and corporate standards have led to several advancements in the innovation and use of sustainable packaging. One of the main ways brand owners of packaged goods have shifted towards sustainability is by using packaging materials that are renewable and biodegradable. Paper and bio-based polymers are examples of materials used in packaging to replace plastic, metal, or glass. |

Bio-based polymers are increasingly being evaluated for their use in creating bioplastics that maintain the same barrier functionalities that synthetic plastic films have, such that they can replace them. Paper has long been used as a packaging material, but paper sizing and barrier coatings must be applied to make it a viable material in certain applications, such as preserving the freshness of foods and preventing permeation or absorption of moisture, oil, and grease. Alginates serve as an ideal biomaterial to provide the perfect mix of sustainability, biodegradability, and functionality to facilitate the creation of sustainable packaging through bioplastic formation, paper sizing, or barrier coating operations.

Scogin® Alginates

Scogin® alginates are biopolymers derived from brown seaweed sustainably harvested from the Norwegian coastline. They are produced by extracting alginic acid from seaweed and adding sodium carbonate to create sodium alginates:

Seaweed Raw Material ▷ Washing/Grinding ▷ Extraction ▷ Screening/Filtering ▷ Precipitation ▷ Alginic Acid ▷ Sodium Alginate

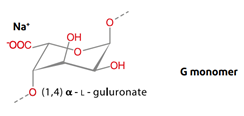

Chemically, Scogin® is composed of two monomers: (1-4)-linked ß-D-mannuronate, also known as the M monomer, and α-L-guluronate, also known as the G monomer.

|

|

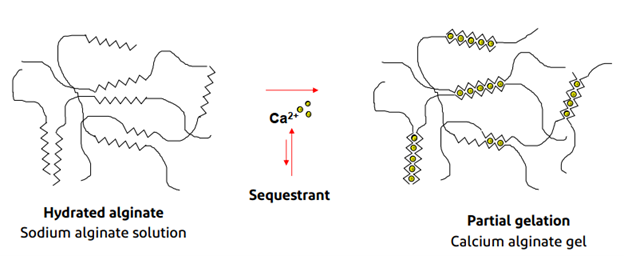

The polysaccharides formed from these monomers have differing proportions of M and G sequences, called blocks. The G-blocks provide sodium alginate gelling capabilities when exposed to calcium ions in water. Unlike other hydrocolloids that form gels and require heat to induce gelation, alginates will undergo gelation in cold water, providing an easier mechanism for creating gels. The M-G block ratio within the alginate ultimately determines gel strength, with alginates containing higher G-block content forming harder gels. The visualization of the mechanism in which gelation occurs is detailed below, referred to as the egg-box model.

|

Gelation is one of the key properties of alginates in the context of forming bio-based plastic films. When alginates are not exposed to calcium, however, they can serve as rheology modifiers and film formers. These properties make the alginates useful for paper sizing and barrier coating applications.

Scogin® Alginates in Packaging Applications

When Scogin® alginates are dispersed in water, they serve as excellent film formers and rheology modifiers. Both paper sizing and barrier coating applications rely on these properties to reduce the absorption or permeation of fluids.

Paper Sizing

| Unsized paper or paper sized to an insufficient degree is not an ideal substrate for printing onto packages. This is because paper is naturally porous. In the case of paper sizing, Scogin® alginates create a film that covers and fills voids to reduce porosity near the paper’s surface. This prevents the absorption of ink systems too deeply into the paper, which would cause a loss in image distinctness through blotting and potential color mixing. |

|

Barrier Coatings

| Porosity also poses an issue for paper when it comes to stains from grease and oil in foods. When IFF's alginates are used as a film former for barrier coatings onto paper, they can improve the grease and oil resistance of paper due to their slight amphiphilicity. This repellency is prounounced when combined with other ingredients such as hydrophobically-modified starch. |

|

In both the paper sizing and barrier coating applications, the rheology modifying properties of IFF's alginates allows films to be formed that have better leveling properties to reduce surface defects and improve coverage. This maximizes the efficacy of inks, paper sizing, and barrier coatings. Scogin® alginates, like other IFF alginates, are biodegradable and have food contact approvals, making them an ideal choice as many food-based paper packaging producers aim to make their packaging more sustainable.

Bioplastics

| As mentioned, Scogin® can also be used to create bioplastics that create packaging films. When Scogin® alginates are introduced to calcium ions in water, G-blocks within the alginate polysaccharide instantly form ionic bonds that induce gelation. The gelling process also cross-links the alginate biopolymers to create castable thin films. When these gel films are dried, they can serve as biodegradable films that may be further modified in terms of performance to replace traditional plastic films made using synthetic polymers. |  |

How to Use Scogin®

The three available grades of Scogin® alginates are listed below with specifications.

| Grade | Viscosity (1% solution, cP) | Suggested use level % | Mesh |

| Scogin® IN2420 | 15–25 | 0.1–1.0 | 18 |

| Scogin® LDH | 50–70 | 0.1–1.0 | 25 |

| Scogin® MV | 350–500 | 0.1–1.0 | 18 |

If the application for Scogin® pertains to paper sizing or barrier coatings, the grade selection should mainly be based on viscosity, as coating methods vary in terms of the specific viscosity range required to apply desired coat weights. As a separate consideration, coating solutions with higher viscosities tend to have better holdout properties on paper, which may be useful in cases where the coating paper has very high porosity.

If Scogin® alginates are to be used for bioplastic applications, the following information can be used to select a sequestrant and calcium source for gelation, depending on solution pH and desired gel properties:

|

Dispersion equipment is required to prepare solutions with Scogin® alginates. Scogin® should be pre-blended with any other dry components that may be added into formulations prior to mixing at high speed. Scogin® grades with finer mesh sizes tend to hydrate quicker but more shear is required to avoid lumping.

Summary

Scogin® alginates are sustainably sourced biopolymers derived from brown seaweed. They, alongside other IFF alginates, provide the necessary functionality to create both sustainable and high-performing food packaging materials. As natural film formers, rheology modifiers, and gelling agents, Scogin® has excellent utility in paper sizing, barrier coating, and bioplastic films. Since the biopolymers of Scogin® and other IFF alginates are also sustainably sourced, biodegradable, safe, and have food contact approvals, they perfectly coincide with the aims of sustainable food packaging manufacturers. ChemPoint is here to answer questions you may have about IFF alginates for your packaging applications and help you obtain a sample. Click below to take your next steps.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - Mexico