Select Your Region

Acrylic Resins Explained: Industrial Applications

Understanding Acrylic Resins

What is acrylic resin?

Chemically speaking, acrylic resins are raw materials composed of synthetic polymers made from monomers such as acrylic acid, methyl methacrylate, and butyl methacrylate. Compared to other types of resins, acrylic resins are unique in that they exhibit extremely high transparency and light transmission due to a relatively amorphous structure, which minimizes light scattering. Acrylic materials transmit around 92% of visible light, as does glass. Acrylic is quite durable, providing good resistance to wear and tear, and exhibits good resistance to weathering, preventing degradation when exposed to varying outdoor conditions.

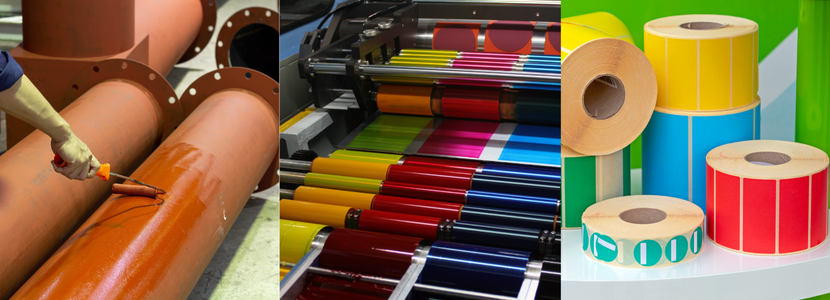

Coatings, Inks, and Adhesives

Acrylic resins are highly soluble in a number of organic solvents and can also be polymerized as a dispersion in water to create emulsions. This allows them to be used as a binder for the basis of coating, adhesive, and ink formulations. Upon curing, these formulations harden to form films that maintain much of the same properties described in the previous section, contributing to high durability and clarity. Manufacturers of acrylic resins usually offer different options based on varying monomer chemistry that changes the resultant acrylic polymer backbone. This allows formulators to select resins that optimize various properties needed to create different formulations, such as flexibility, solubility, toughness, and formulation compatibility. For example, a resin made from methyl methacrylate may impart lower flexibility but higher film toughness, making it more useful as a binder for an industrial topcoat formulation. Comparatively, a resin made from butyl methacrylate may impart higher flexibility and lower abrasion resistance, making it ideal for an adhesive formulation.

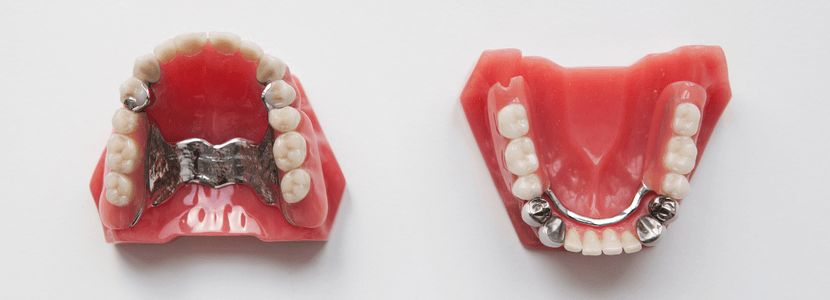

Plastic Parts

These resins are also thermoplastic, allowing them to be thermally formed into various shapes. Acrylic resins such as PMMA can be melted into liquids at high heat and compounded with other ingredients. They can then be cast, extruded, molded, or formed into various shapes, such as sheets, blocks, or custom formats. Recalling the high degree of transparency acrylic materials offer, parts such as automotive taillights, optical lenses, and lighting fixtures are often made from acrylic resins. PMMA may also be used in dental applications, where pigments or dyes may be added to create parts that mimic natural teeth and gums. Parts such as dentures and artificial teeth are commonly made from acrylic.

1

Often, acrylic resins and epoxy resins may be confused with one another due to the similarity in their applications. However, epoxy resins are thermosetting materials, in comparison to the thermoplastic acrylic resins described above. Unlike acrylic resins, epoxy resins require a hardener (also known as a curing agent), which cross-links their polymer network to achieve final properties. Due to this cross-linking, epoxy resins offer properties that make them relatively more durable and resistant to degradation due to chemical and heat exposure than acrylic resins. However, acrylic resins inherently provide superior UV resistance and optical clarity. Therefore, though both epoxy and acrylic resins may be used in applications such as coatings, adhesives, and molded parts, one or the other is selected based on specific demands per application.

ChemPoint's resin portfolio

ChemPoint offers acrylic and epoxy resins from Mitsubishi Chemical Group. With manufacturing and technical support resources located across the United States, EMEA, and the Asia–Pacific region, Mitsubishi Chemical Group is renowned for its portfolio of market-leading ingredients for formulators. Click below to explore Elvacite® and Dianal acrylic bead resins, Diakon® and Elvakon® injection molding and coextrusion resins, and jER™ epoxy resins. Contact us, and one of our technical experts will gladly provide samples, pricing, and formulation assistance.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States