Select Your Region

Impact Modifiers for Composite Utility Infrastructure

The investment surrounding data centers is seeing massive growth for polymer materials that can meet the demand and improve life cycle cost. Historical utility poles were comprised of treated wood, steel, or even concrete electrical poles and structures. Compared to traditional materials, fiber-reinforced polymer (FRP) composites provide longer service life as they are more durable and require less maintenance.

With such investments developed for resilience and an extended life cycle, fiber-reinforced polymers still require additives that improve weatherability and overall impact strength, making it critical to select the right impact modifiers for the longevity of the fiberglass composite poles.

Choosing the Right Impact Modifiers for Epoxy or Unsaturated Polyester

Dow PARALOID™ Core-Shell Impact Modifiers have a rubber core with a low glass transition temperature (Tg) with a methyl methacrylate-butadiene-styrene (MBS) shell. The primary advantage of Dow PARALOID™ Impact Modifiers and Processing Aids is that they are available in predetermined particle sizes. This allows the impact modifier to disperse evenly and couple within the polymer’s matrix, creating mixing efficiencies that strengthen engineering plastics and composites.MBS Impact Modifiers

Dow PARALOID™ MBS Impact Modifiers are designed to provide exceptional cold-temperature impact in a wide range of engineering plastics. These include polycarbonate, polycarbonate alloys (PC/ABS, PC/PBT), and polyesters. When compared to other acrylics available in the market, core-shell impact modifiers offer improved properties to polycarbonates and blends, such as exceptional low-temperature impact performance, excellent weatherability and heat aging, and exceptional mold-in colorability.

Dow PARALOID™ MBS Impact Modifiers’ core-shell technology is optimized for liquid thermoset resins because its narrow, submicron particle size is not influenced by processing, and each impact modifier powder grain is an aggregate of billions of particles.

Toughness efficiency is achieved through the even dispersion of the large aggregate into individual particle sums.

Grade Spotlight

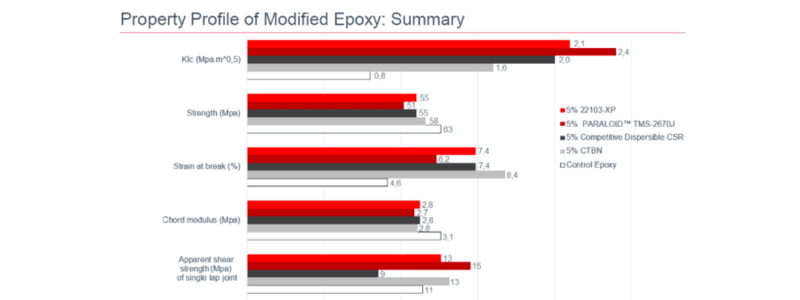

PARALOID™ TMS 2672 is an MBS core-shell impact modifier from Dow, designed to enhance mechanical properties for thermosetting and epoxy resins. TMS-2672 enhances FRP composites by improving impact strength at both room and low temperatures, increasing elongation at break, and boosting fatigue resistance, while maintaining a low viscosity for easy processing with epoxy and methyl methacrylate resins. It also strengthens adhesion properties and retains the glass transition temperature, ensuring long-term performance and durability.

Please note: 22103-XP is also known as PARALOID™ TMS-2672.

Composite utility poles are developed for resilience and the extended life cycle that can improve cost savings compared to wood poles, which require replacement every 30 to 40 years. By incorporating Dow PARALOID™ MBS Impact Modifiers, companies can increase capacity, transmission, and distribution of the existing electrical grid, as well as improve reliability and the ability to recover from outages. If you would like to learn more, click the link today to talk to one of our technical experts for formulation guidance.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States