Select Your Region

Momentive Tufel™ III Silicone Rubber 92006

Momentive performance materials are high-performance silicone elastomers that support a variety of industries. The Tufel™ III silicone rubber 92006 series is biocompatible for extruders and calendered manufacturers of elastomeric components.Tufel™ III 92506 and 92656 are 50- and 65-durometer-hardness, two-component silicone grades comprising high resilience without requiring post bake in most applications, thereby enhancing production efficiency.

The Tufel™ III 92006 series offers a longer service life in highly mechanical applications, making them suitable for peristaltic pump tubing, gaskets, seals, and valves. With a peroxide-free cure system and low volatile bases, the Tufel™ III 92006 series ensures minimal porosity and a tight surface cure.Features and Benefits of Tufel™ III 92006 Series

Features and Benefits of Tufel™ III 92006 Series

- Low compression set

- Available in 50 or 65 durometer hardness

- Outstanding elastic memory

- Biocompatible with ISO 109993 and USP Class IV requirements

- Nonblooming properties

- Low hysteresis

- Peroxide-free cure system

- Tight surface cure

- Translucency

- No post baking requirements

- Low volatile bases to minimize porosity

- Enables high output rates

Potential Uses and Applications for Tufel™ III 92006 Series

Medical/Healthcare

- Fluid and drug delivery tubing

- Volumetric

- Enteral pumps

- Ambulatory pumps

- Hose/tubing used in pharmaceutical production

- Gaskets, seals, and valves

Consumer Goods

- Tubing used for dispensing foods and beverages

- Gaskets, seals, and valves

General Industrial

- Tubing used in chemical/industrial processing plants

- Tubing used in laboratory peristaltic pumps

- Gaskets, seals, and valves

Physical Properties of Uncured Tufel™ III Silicone Rubber 92006 Series

Specific gravity: 1.12

Appearance: Translucent

Polymer classification (ASTM-1418): VMQ

Williams plasticity range (ASTM D-926): 200–300

Specific gravity: 1.16

Appearance: Translucent

Polymer classification (ASTM-1418): VMQ

Williams plasticity range (ASTM D-926): 210–310

Momentive Tufel™ III Silicone Rubber Test Performance Data

Hysteresis

The chart below measures the loss of elastic energy for an elastomer when it is dynamically deformed and allowed to return to its original state. This test comprises an elongating standard ASTM tensile dumbbell to 100% stretch, then returning to the original position. The measure of hysteresis is in percentage, and the chart shows Tufel™ III 92506 and 92656 silicone compounds have lower hysteresis loss than competitive platinum and peroxide-curable silicones when used in tubing applications. When a silicone has lower hysteresis, this can result in less material fatigue over the lifetime of the elastomer in mechanically dynamic applications.

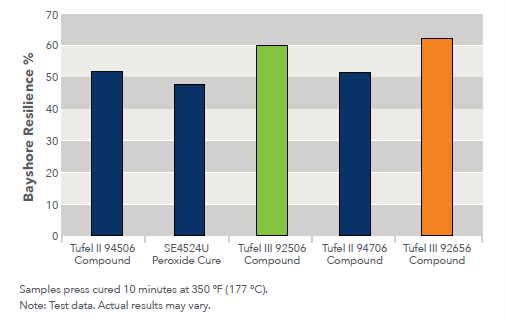

Resilience

The chart below exhibits how Tufel™ III silicone rubbers showcase a higher resiliency than competitive platinum and peroxide-curable silicone elastomer materials.

Summary

If you are interested in learning more about the Momentive Tufel™ III 92006 series, click to talk to a technical specialist today.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States