Select Your Region

Improve Structural Adhesives with Impact Modifiers

Structural adhesives are increasingly used in applications requiring lightweight design, high bond strength, and long-term durability, especially in industries such as automotive, aerospace, construction, and electronics. While many adhesive systems deliver strong bonding performance, challenges often arise in achieving impact resistance, toughness, and durability under demanding service conditions.

PARALOID™ Impact Modifiers provide an advanced solution, offering formulators a reliable way to balance adhesive strength and toughness, ensuring that structural adhesives can withstand thermal, mechanical, and environmental stress.

Role of Impact Modifiers in Structural Adhesives

Structural adhesives from epoxies and acrylates are widely used for bonding metals, plastics, and composites. However, these systems can be inherently brittle, limiting performance under impact or peel stress. Impact modifiers work by introducing a toughening mechanism within the adhesive matrix. Acrylic or MBS impact modifiers like PARALOID™ Impact Modifiers form discrete rubbery domains that absorb and dissipate energy, reducing crack propagation and increasing resistance to sudden stresses.Epoxy Adhesives

Epoxy adhesives are strong but brittle. PARALOID™ Impact Modifiers improve impact resistance, peel strength, and crack resistance without significantly reducing tensile strength. Epoxy adhesives are primarily used for metal-to-metal and composite structural bonding in automotive, aerospace, and construction.Acrylic (Methacrylate) Adhesives

Acrylic adhesives already have good adhesion and fast cure but can lack toughness. PARALOID™ Impact Modifiers enhance the durability and toughness under peel, shock, or vibration stress. Typically used to bond plastics, composites, and metals in transportation, wind energy, and industrial assembly.Why Choose PARALOID™ Acrylic Impact Modifiers?

- Improved Impact Resistance & Toughness: Enhance adhesive formulations by reducing brittleness and improving crack resistance.

- Enhanced Peel & Shear Strength: Allow adhesives to maintain high bond strength even under stress conditions.

- Thermal & Environmental Stability: Maintain adhesive performance under high temperatures, humidity, and aggressive chemicals.

- Dispersibility: Easy to disperse core-shell-rubber particles into formulations without compromising adhesive cure or viscosity.

Applications in Structural Adhesives

Automotive & Transportation

Bonding lightweight plastics and composites to metal frames, delivering high crash resistance.

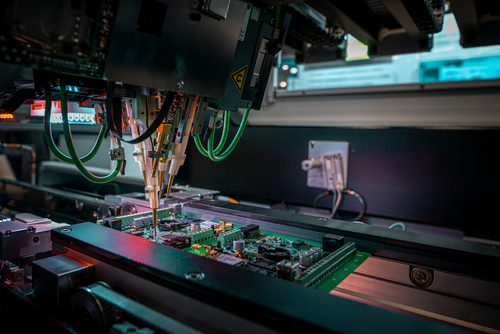

Electronics & Appliances

Enhancing the reliability of adhesives exposed to vibration, thermal cycling, and mechanical impact.

Building & Construction

Toughened adhesives for structural panels, flooring, and composite reinforcement.

Aerospace & Industrial

Formulating adhesives capable of withstanding dynamic loads and harsh environmental conditions.

Conclusion

As industries demand lighter, stronger, and more durable bonded structures, the role of impact modifiers in structural adhesives becomes critical. PARALOID™ Impact Modifiers deliver the toughness and reliability needed for adhesives to perform under the most demanding conditions. Click the button to talk to a technical expert today about which grade works best for your adhesive formulation.

PARALOID and the DOW Diamond are trademarks of The Dow Chemical Company ("Dow") or an affiliated company of Dow.

NOTICE: No freedom from infringement of any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for determining whether products and the information in this document are appropriate for Customer's use and for ensuring that Customer's workplace and disposal practices are in compliance with applicable laws and other government enactments. The product shown in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made may not have been approved for use in all countries. Dow assumes no obligation or liability for the information in this document. References to “Dow” or the “Company” mean the Dow legal entity selling the products to Customer unless otherwise expressly noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

NOTICE: No freedom from infringement of any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for determining whether products and the information in this document are appropriate for Customer's use and for ensuring that Customer's workplace and disposal practices are in compliance with applicable laws and other government enactments. The product shown in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made may not have been approved for use in all countries. Dow assumes no obligation or liability for the information in this document. References to “Dow” or the “Company” mean the Dow legal entity selling the products to Customer unless otherwise expressly noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States