Select Your Region

Power Distribution Reliability for Substations, Switchgear, and Critical Power Systems

Why power distribution is changing now

Power distribution has moved from background infrastructure to a first-order operating constraint for modern facilities and utilities. Reliability is increasingly defined in practical terms: keeping the system functional through credible disturbances and isolating problems without losing the entire network.

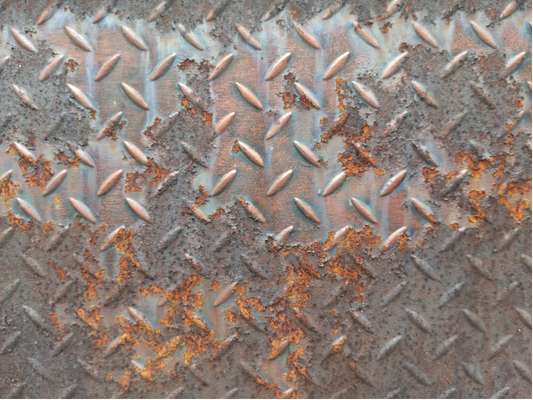

At the same time, much of power distribution lives outdoors and in mixed industrial environments where moisture, contamination, and temperature swings are persistent. Those exposures accelerate degradation pathways that accumulate quietly—until they show up as heat, binding mechanisms, nuisance operations, or unsafe switching conditions.

This is pushing organizations toward more rigorous, auditable reliability practices—where inspection scope, test methods, tolerances, and action thresholds are defined well enough to be repeatable across crews and sites.

What you will get from this guide

This page is a practical field guide for making power distribution decisions that hold up in the real world—from specifying and maintaining substation assets to qualifying practices that protect uptime. It is written for teams responsible for switching reliability, maintenance execution, and sourcing decisions across substations and critical power systems.

On this page (table of contents)

- Quick orientation (the 60-second version)

- The system view (what the end-to-end system must do)

- What fails in the real world (failure modes and why they happen)

- Decision criteria (how to choose the right approach)

- Guidance for specifiers (designing and specifying the right solution)

- Guidance for operators and maintenance (protecting uptime in the real world)

- Guidance for procurement and sourcing (risk, continuity, and qualification)

- Where ChemPoint fits (how we help)

- Recommended next steps

- FAQs

Quick orientation (the 60-second version)

Power distribution is the set of assets and interfaces that safely move electricity from higher-voltage networks down to the points of use—substations, switchgear, breakers, disconnects, connectors, terminations, and the mechanisms that operate them. The system must conduct efficiently, interrupt safely, and operate predictably over long service lives.

Many reliability problems are interface problems. Small changes at contact surfaces, terminations, seals, and operating linkages can cascade into heating, arcing risk, mechanical nonperformance, and safety exposure—often before a failure is obvious.

A reliable program starts with systems thinking: define boundaries and interfaces, define operating conditions, and align maintenance and testing to the failure modes that matter most. Reliability methods are commonly used to evaluate and improve expected outcomes, rather than relying on intuition alone.

Back to Table of Contents

The system view (what the end-to-end system must do)

Key interfaces typically include electrical contact surfaces, terminations and connectors, insulating interfaces (bushings and terminations), sealing boundaries, and mechanical linkages that translate a human or motor input into a switching action. These are the points where contamination films, corrosion products, and loss of contact pressure can translate into heating and accelerated degradation.

Maintenance testing specifications emphasize that “suitable for continued service” is not a vibe check; it is determined through inspections and tests aligned to applicable standards and manufacturer tolerances. That framing helps teams focus on the interfaces that can be measured and acted on.

Operating conditions that drive design choices

Outdoor substations live in variable environments: humidity, condensation cycles, dust, salt exposure, and industrial pollutants. These conditions increase corrosion and contamination risk, particularly at exposed conductive interfaces and at enclosure boundaries with poor ingress control.Operational factors matter, as well: switching frequency, fault duty, loading profiles, and accessibility. Reliability approaches benefit from explicitly mapping environment severity and duty cycle to inspection or testing scope and acceptance thresholds.

Real-world constraints that shape decisions (space, uptime, safety, and qualification)

Distribution work is constrained by outage windows, safety rules, and the need to restore service predictably. Those constraints shape what can realistically be inspected, tested, corrected, and documented during maintenance events.Qualification constraints also shape decisions. When a change could affect safe switching performance or long-interval assumptions, documentation and change control become part of reliability—not bureaucracy.

Back to Table of Contents

What fails in the real world (failure modes and why they happen)

Field failures often present first as symptoms: hotspots, abnormal heating, stiffness or binding in mechanisms, visible tracking, nuisance trips, or unexpected changes in test readings. Many of these issues are detectable earlier than most organizations think—if inspection and testing are designed around the right failure modes.

Below are recurring failure modes across power distribution assets. The physics is consistent: interfaces degrade, and degraded interfaces become heat, arcing risk, or mechanical nonperformance.

Contact interface degradation (rising resistance and heating)

Contact surfaces degrade through contamination films, corrosion products, loss of contact pressure, and wear. As resistance rises, localized heating rises, accelerating degradation and reducing remaining life margin.The practical takeaway is that “good contact” is an engineered and maintained condition. It must be verified using appropriate methods and acceptance criteria for the asset class and duty.

Corrosion and moisture ingress (environment-driven reliability loss)

Environmental exposure and moisture ingress increase corrosion risk and can degrade both conductive interfaces and insulating boundaries over time. This is a persistent reliability driver in substations and distribution environments.This is why environmental controls and protective approaches are increasingly central to distribution reliability—not just preferred, but as direct controls on degradation pathways.

Operating mechanism wear or binding (failure to operate as intended)

Switching devices rely on linkages, pivots, springs, and moving assemblies that must operate predictably. Wear, contamination, and loss of effective mechanism condition can increase operating force and reduce reliability—especially under adverse conditions.Mechanism problems are expensive when discovered during forced events. Field programs that include consistent operational checks and condition-based maintenance reduce that surprise risk.

Aging asset failure mechanisms (breakers, reclosers, disconnects, and surge protection)

Failure mechanisms differ by device class and design era, which is why asset-management-informed maintenance planning is common: teams prioritize effort where the failure probability and consequence are highest.Reliability analysis methods can support those prioritization decisions and help justify changes to design, maintenance scope, or replacement strategy.

Back to Table of Contents

Decision criteria (how to choose the right approach)

Reliable distribution programs balance performance requirements, environmental constraints, and maintenance execution realities. The right approach is the one that holds up in your operating conditions and is maintainable within your outage windows, safety constraints, and staffing model.

Tradeoffs show up everywhere: deeper testing scope versus outage time, higher environmental protection versus upfront effort, tighter thresholds versus more corrective work. The goal is controlled risk and predictable performance, not theoretical perfection.

Performance and reliability requirements

Start by defining what reliable means for your asset class: expected switching performance, acceptable heating, acceptable insulation condition, and acceptable probability of failure over time. Preventive maintenance impact is often evaluated with structured reliability approaches, rather than intuition.Then tie metrics to action. If a measurement does not drive a decision threshold—monitor, correct, refurbish, and replace—it becomes data without leverage.

Compatibility/Constraints and tradeoffs

Equipment suitability for continued service is commonly framed against standards and manufacturer tolerances. Maintenance testing specifications explicitly anchor programs to that kind of tolerance-based acceptance logic.In practice, selection criteria should be system compatible: evaluate how any practice interacts with contacts, insulation boundaries, and operating mechanisms under the environment and duty you actually have.

Maintainability and lifecycle considerations

A reliability program that cannot be executed consistently becomes a reliability risk. Reliability-centered maintenance frameworks are used in power delivery to prioritize tasks based on consequence and controllability while balancing cost and service outcomes.This lifecycle lens also supports standardization. Repeatable procedures, acceptance criteria, and documentation reduce human-variation risk across crews, sites, and contractors.

Design and selection checklist:

- Define the asset boundary and interfaces (contacts, terminations, mechanisms, seals) before selecting scope

- Document operating conditions (environment severity, duty cycle, switching frequency, outage-window constraints)

- Align inspection or testing methods to applicable standards and manufacturer tolerances

- Set action thresholds that drive decisions (monitor, correct, refurbish, replace)

- Standardize procedures and documentation for repeatability across crews, sites, and contractors

- Validate compatibility and manage substitution risk at critical interfaces

- Use change control (training, documentation updates, and qualification readiness for program changes)

Back to Table of Contents

Guidance for specifiers (designing and specifying the right solution)

Specifiers have leverage because upstream choices determine downstream maintainability. The most effective spec packages define performance intent and the evidence required to verify that intent during commissioning and maintenance.

A reliability-minded spec starts with clarity: system boundaries, interfaces, operating conditions, and acceptance criteria. That prevents ambiguous handoffs between design, construction, commissioning, and operations—especially when multiple contractors and crews touch the system over time.

What to validate during design review

Validate that the design addresses environmental exposure and ingress risk explicitly, rather than assuming enclosures and interfaces will “just be fine.” Substation exposure and degradation risk are widely recognized as reliability drivers that need deliberate controls.Validate maintainability: access for inspection or testing, realistic outage windows, and clarity on how the condition will be verified against tolerances. Testing frameworks are commonly anchored to repeatable inspections and tolerance-based acceptance, not subjective judgment.

What to document in the spec package (so it survives handoffs)

Document inspection or testing scope, acceptance tolerances, and the standards or manufacturer tolerances that define pass or fail. Maintenance testing specifications emphasize that suitability for continued service is determined through such aligned inspections and tests.Also, document change control expectations. Substitution at critical interfaces can create hidden incompatibilities; documented evaluation and approval practices are a reliability control, not paperwork.

Back to Table of Contents

Guidance for operators and maintenance (protecting uptime in the real world)

Operators live in the constraint reality: limited windows, safety requirements, and the need to restore service predictably. The objective is to execute the right work consistently, focused on the failure modes that drive outages and safety exposure.

Maintenance testing specifications are designed to create repeatability, so two different crews can assess suitability for continued service using consistent methods and tolerances. That repeatability is a reliability advantage in itself.

What to monitor and why

Monitor indicators that map directly to failure modes: heating or contact condition indicators, insulation condition indicators, and evidence of environmental ingress or contamination risk. The goal is early detection that enables planned intervention, rather than emergency work.Add an asset-management lens when possible—device class and age matter, and failure mechanisms differ across breaker, recloser, and disconnect families. Maintenance strategy benefits from understanding those device-specific patterns.

Maintenance practices that prevent recurring issues

Recurring issues usually trace back to interfaces: contacts, terminations, mechanisms, seals, and environmental barriers. A mature program defines corrective actions that address root causes, rather than repeatedly treating symptoms.Reliability-centered maintenance approaches can help prioritize tasks that create the largest risk reduction per unit of effort, especially when staffing and outage windows are constrained.

Where standardization matters most

Standardization matters most where variation changes outcomes: inspection procedures, acceptance thresholds, documentation practices, and any steps that affect safety-critical switching performance. Standardized methods support repeatable outcomes across crews and contractors.Standardization also improves sourcing and contractor management because it clarifies evidence requirements and acceptance logic, reducing rework and surprise nonconformances.

Back to Table of Contents

Guidance for procurement and sourcing (risk, continuity, and qualification)

In power distribution, procurement is about continuity and reliability risk as much as unit price. The goal is to prevent substitutions or sourcing shortcuts from degrading safety, reliability, or maintainability at critical interfaces.

A disciplined approach treats qualification and documentation readiness as part of the definition of done, especially when a change affects contacts, mechanisms, insulation boundaries, or environmental protection assumptions.

Qualification requirements and documentation readiness

Treat qualification as a reliability control; procedures, test methods, and documentation define whether outcomes are repeatable and safe in the field. Standardized inspection or testing frameworks are commonly used to support that repeatability.Qualification rigor typically increases as consequence increases, especially across multisite systems where inconsistency itself becomes a failure-mode amplifier.

Approved sourcing paths and substitution risk

Substitution risk is highest when the change touches conductive interfaces, insulating boundaries, or operating mechanisms. Without change control, substitutions can create hidden incompatibilities that only show up as premature degradation.Define which categories require formal review and ensure suppliers/partners can provide the documentation needed to support that review.

Continuity planning (lead times, second sources, and change control)

Continuity planning is about avoiding forced compromises. If critical items are unavailable, teams may substitute under pressure and unintentionally create reliability risk. A standards-aligned program anticipates high-consequence needs and aligns sourcing to outage windows and documentation requirements.Back to Table of Contents

Where ChemPoint fits (how we help)

Reliable power distribution depends on equipment that operates safely, predictably, and with minimal unplanned downtime. ChemPoint supports these goals by offering materials and lubricants engineered to withstand environmental exposure, reduce wear, and extend maintenance intervals across critical components.For electrical contacts and mechanisms, MOLYKOTE® specialty lubricants provide consistent performance under load, helping reduce friction, prevent galling, and maintain reliable actuation in switches, breakers, and disconnects. These solutions support long‑interval maintenance and dependable operation, even in challenging environments.

For exposed metal components, Rilsan® powder coatings deliver outstanding corrosion resistance and protection from moisture, chemicals, and environmental contaminants. This helps extend the service life of housings, brackets, and hardware that are routinely exposed to harsh outdoor conditions.

To make it easy for power‑distribution professionals to evaluate the right solution, ChemPoint provides application‑focused product pages, technical data, and clear next steps. Visitors can quickly connect with a product specialist, request data sheets, or check pricing and availability—ensuring fast access to support, quotes, or technical guidance when needed.

Back to Table of Contents

Recommended next steps

If your priority is improving switching reliability and reducing nuisance events in substations or critical distribution systems, the practical next step is to align your failure modes and operating conditions to a documented selection and maintenance approach, then route decisions through the support and sourcing paths that match your risk profile.Talk to a power distribution specialist at ChemPoint today!

Back to Table of Contents

FAQs

What’s the difference between grid reliability and power distribution reliability?

Grid reliability is the broad system concept: keeping electricity adequate, secure, and stable through expected disturbances. Power distribution reliability is the practical subset: how well substations, switchgear, and distribution interfaces perform day-to-day and during events.Why do many issues show up first at connectors and interfaces?

Interfaces are where conductive surfaces, pressure, environment, and human work intersect. Small condition changes at those boundaries can create heating and accelerated degradation that cascades into broader reliability risk.How do maintenance testing specifications help in practice?

Maintenance testing specifications provide a structured approach to inspections and tests to assess suitability for continued service against standards and tolerances, improving repeatability across crews and reducing judgment-only variability.When should you use reliability-centered maintenance (RCM) versus time-based maintenance?

RCM is commonly used when consequences vary and resources are constrained because it prioritizes tasks around consequence and controllability while balancing maintenance cost and service reliability.How do you reduce substitution risk in critical distribution assets?

Define which changes require formal review, document what evidence is required, and use change control to prevent substitutions from creating hidden incompatibilities at conductive and insulating boundaries.Back to Table of Contents

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States