Enhancing Data Center Resilience and Performance with SI Group Solutions

Select Your Region

Enhancing Data Center Resilience and Performance with SI Group Solutions

As cloud computing and AI adoption accelerates, the critical infrastructure and operations of data centers must be able to keep up with the demand. These complex facilities must meet rigorous performance standards for thermal management, electrical insulation, structural integrity, and long-term durability often under continuous operation. From polymer protection to structural performance, the SI Group’s advanced additives help manufacturers and builders enhance the durability, reliability, and efficiency of components used throughout the data center value chain.

Antioxidants

Data centers operate under demanding thermal loads, with continuous heat cycling from server racks, power distribution units, and HVAC systems. Polymer materials used in cable insulation, wire jackets, fan housings, and structural supports are vulnerable to oxidative degradation over time. SI Group’s phenolic and aminic antioxidants, such as WESTON™ and NAUGARD™, provide thermal oxidative stability to polymers like polyolefins (e.g., PE, PP), polyamides, and styrenics. These antioxidants extend the service life of:

UV Stabilizers

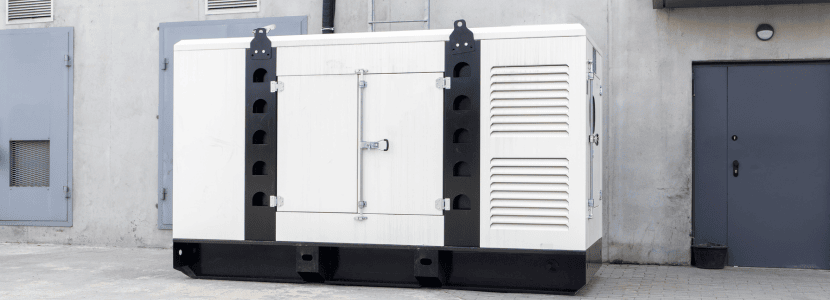

Many critical data center components are housed outdoors, including HVAC units, power backup generators, and telecommunications interfaces. Polymer materials exposed to sunlight can suffer from photo-oxidative degradation, leading to embrittlement, discoloration, or cracking. SI Group’s LOWILITE™ UV stabilizers and light stabilizer blends (including HALS and UV absorbers) are designed to protect polyolefins, TPOs, and engineering thermoplastics used in:

POLYBOND™ Coupling Agents

Data center construction demands materials with excellent dimensional stability, strength-to-weight ratio, and flame retardancy. To meet these requirements, many manufacturers turn to mineral-filled or glass-fiber-reinforced polyolefins and TPOs for cable trays, conduits, wall panels, and rack enclosures. SI Group’s POLYBOND™ coupling agents are maleic anhydride-grafted polyolefins that enhance the interfacial adhesion between the polymer matrix and inorganic fillers or fibers. This improves mechanical properties such as:

ROYALTUF™ Impact Modifiers

Data center facilities often operate in varied climates, including regions with sub-zero temperatures. Brittle failure of plastic components under cold shock can compromise structural integrity or cause service disruptions. ROYALTUF™ impact modifiers, based on rubber-modified styrenics, enhance the toughness and low-temperature impact resistance of engineering thermoplastics used in:

Conclusion

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States