Select Your Region

Solus™ 2300 For High-Performance, Sustainable Coatings

|

As urbanization accelerates and the global population continues to rise, there has been a coinciding rise in the number of automobiles being manufactured, as well as infrastructure projects and industrial facilities being built. Integral to every automobile and many industrial and infrastructure projects are the paints and coatings applied, which provide both decorative and protective functionality. |

Eastman Solus™ 2300Eastman Solus™ 2300 is a cellulose ester developed as a tool for automotive and industrial paint and coating formulators to increase the visual quality, efficiency, and sustainability of their formulations. Solus™ 2300 is a low–molecular weight cellulose acetate butyrate additive widely used to improve rheological properties and reduce defects in solvent-based paint and coating systems. Basic information on the Solus™ 2300 additive can be viewed to the right. |

|

When used as an additive in automotive and industrial coatings, Solus™ 2300 provides the following benefits:

- Optimized metallic pigment flake orientation and increased distinctness of image

- Fewer defects resulting from surface contamination

- Higher efficiency through faster solvent release and dry-to-touch times

- Compatibility with low-VOC systems and sustainable initiatives

Improved Metallic Pigment Control and Distinctness of Image

Metallic pigments are commonly used in high concentrations in automotive basecoats to create a more luxurious appearance and provide better abrasion and UV resistance. These metallic pigments, often small flakes, must be oriented in a specific manner to increase the degree of reflectivity they provide relative to light and viewing angles.

The Solus™ 2300 coating additive helps improve metallic pigment orientation, leveling, surface roughness, film redissolve resistance, and distinctness of image (DOI). Three basecoat formulations were prepared to validate this: the first contained no flow and leveling additives, the second contained microgel, and the third contained Solus™ 2300.

| Basecoat | DOI | Flop Index (Basecoat) | Flop Index (Basecoat/Clearcoat) | Δ Flop Index |

| Control | 69.6 | 9.7 | 7.1 | −2.6 |

| Microgel | 74.1 | 9.9 | 8.1 | −1.9 |

| Solus™ 2300 | 79.6 | 10.8 | 10.0 | −0.8 |

By improving flow and leveling performance, Solus™ 2300 improved DOI, the flop index of the basecoat alone, and the flop index with both the basecoat and clearcoat. In the data above, higher values for DOI and flop index and a lower difference in flop index between the basecoat and basecoat–clearcoat test are preferred. The lower difference in flop index indicates better redissolve resistance, where Solus™ 2300 was able to keep metallic pigments in the basecoat oriented much more favorably when a clearcoat was overlaid. Below are confocal images of the tests that help illustrate the degree of difference in pigment control with and without the Solus™ 2300 coating additive.

|

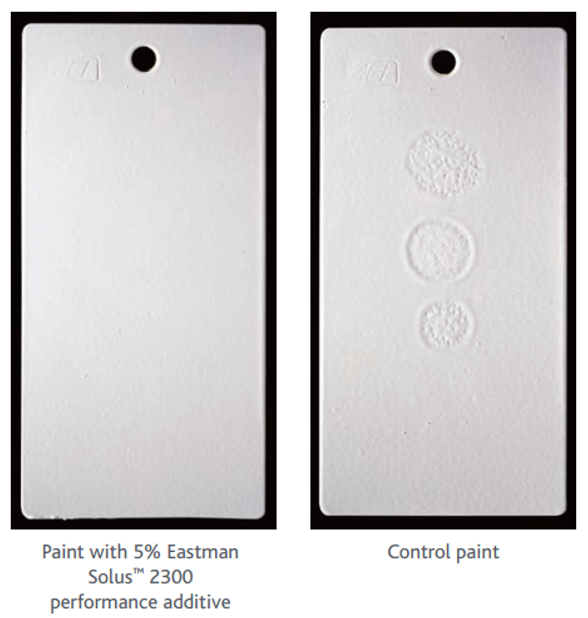

Reduced Surface Defects on Contaminated Surfaces

In all coating processes, ensuring the substrate is clean and free of contaminants is a crucial first step. In cases where contamination is missed or still accidentally present, however, Solus™ 2300 can improve performance on these surfaces. Tests were made with a paint containing 5% Solus™ 2300 and a control without Solus™ 2300. These paints were applied to test panels containing a lubricant sprayed on prior to coating application. The results below depict that Solus™ 2300 displays increased functionality as an additive that can reduce the incidence of paint defects on contaminated surfaces.

|

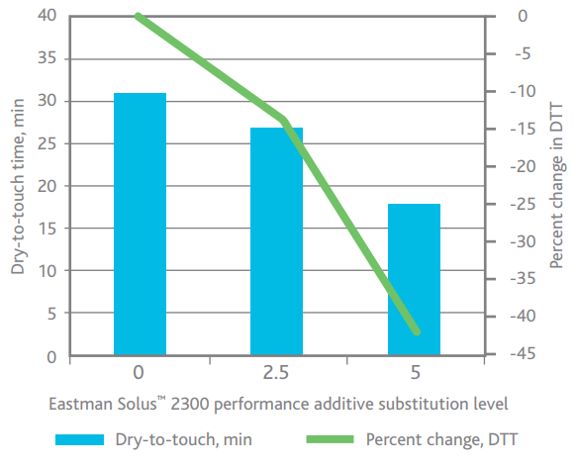

Faster Dry-to-Touch Time

Solus™ 2300 can improve the productivity and efficiency of automotive and industrial paint and coating processes without impacting performance. Tests were run using Solus™ 2300 to replace portions of acrylic polyol resins in a coating formulation to demonstrate the effect of Solus™ 2300 increasing the rate of solvent release. In the data below, up to 5% of the acrylic polyol in the coating formulation was replaced, yielding up to a 40% decrease in dry-to-touch time.

|

In addition to improving dry times, Solus™ 2300 also improves early cure properties. Tests were run with one coating that contained Solus™ 2300 and one that did not, demonstrating its effect on Tg within the first 24 hours of curing. Results indicated that Solus™ 2300 increased coating Tg by 5°C within 24 hours of curing compared to the control, where both coating systems reached equilibrium after seven days of room-temperature cure. This suggests that Solus™ 2300 can improve coating system durability during the early stages of cure.

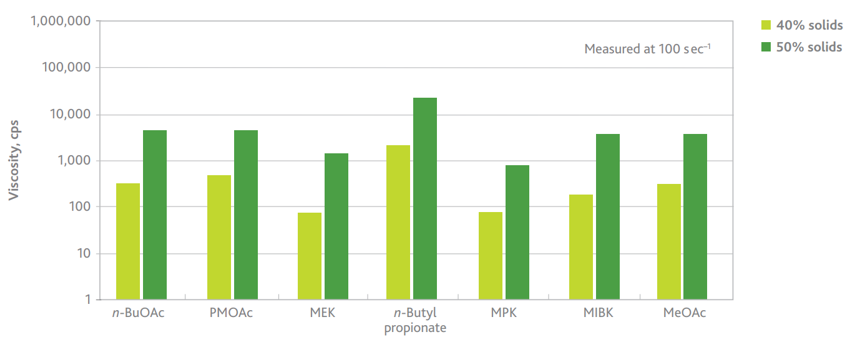

Compatibility with Low-VOC Systems

Solus™ 2300 is a highly compatible additive for most high-solids paint and coating systems and has great solubility in a variety of solvents. Not only is it extremely versatile, but it is also ideal for formulating solvent-based paints and coatings that create safe and sustainable value propositions. Solus™ 2300 has a relatively low intrinsic viscosity and solvent demand, allowing a reduction in VOCs and HAPs that make solvent-based paints and coatings unfavorable from safety and sustainability perspectives. Below is a chart containing information about the viscosity of solutions with Solus™ 2300 in various solvents.

|

Solus™ 2300 is also a naturally derived additive, consisting of approximately 43% bio content originating from cellulose. Thus, using Solus™ 2300 not only provides critical performance improvements to coating formulations as a coating additive but also improves the sustainability of the formulation by increasing the bio content present.

Example Formulations

The paint and coating formulations described in the tests above can be viewed below.

Generic Automotive Basecoat

| Component | Wt % | Formulation Data | |

| Polyester polyol (60% nonvolatile) | 44.0 | Solids as prepared, prior to reducing for spraying (%) | 46.9 |

| Melamine resin (70% nonvolatile) | 18.5 | Application viscosity (#4 Ford cup, sec) | 20.06 |

| Solus™ 2300 additive (40% in n-butyl acetate) | 9.4 | Theoretical solids (%) | 39.6 |

| Wax dispersion (5% nonvolatile) | 19.8 | Measured solids at application (%) | 39.4 |

| Flow additive | 0.7 | Density (lb/gal) | 8.25 |

| Aluminum flake (70% nonvolatile) | 6.6 | Density (g/L) | 989 |

| Solvent blend (50/50 xylene/aromatic 100) | 1.0 | - | - |

| Total | 100.0 | - | - |

Industrial Coating

Part A: Grind

| Component | Supplier | Wt % |

| SETALUX® 1903 BA-75 | Allnex | 21.0 |

| DISPERBYK-110 | BYK | 0.6 |

| Ti-Pure™ | Chemours | 31.3 |

| 45% n-butyl acetate, 35% MAK, 15% MEK, 5% EB acetate solvent blend | - | 1.5 |

| Total | - | 54.4 |

Part A: Letdown

| Component | Supplier | Wt % |

| SETALUX® 1903 BA-75 | Allnex | 18.5 |

| DABCO® T 12 catalyst | Evonik | 0.1 |

| Solus™ 2300 additive | Eastman | 3.1 |

| DISPARLON OX-60 | King Industries | 0.7 |

| BYK-306 | BYK | 0.1 |

| 45% n-butyl acetate, 35% MAK, 15% MEK, 5% EB acetate solvent blend | - | 4.9 |

| Total | - | 27.4 |

Part B

| Component | Supplier | Wt % |

| Desmodur® N 3390 | Covestro | 18.2 |

Summary

Solus™ 2300 is the ideal flow control and leveling additive for automotive and industrial paints and coatings to increase performance and sustainability significantly. This additive promotes better visual quality through improved metallic flake orientation and distinctness of image and reduces the number of surface defects, even on contaminated surfaces. Solus™ 2300 also decreases the dry-to-touch time and the development of early-cure durability of coatings. It is also conducive to sustainable formulation development by being naturally derived and compatible in high solids, low-VOC formulations. Click below to discuss your paint or coating application and request more information or a sample of Solus™ 2300 today.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States