Optimize LDPE Film Block Resistance and Clarity with SYLOBLOC®

Select Your Region

Optimize LDPE Film Block Resistance and Clarity with SYLOBLOC®

Polyethylene films are widely used in applications such as packaging, agriculture, and construction due to their durability, flexibility, and ability to resist moisture and chemicals. These films often incorporate antiblocking agents to ensure freshly made film layers do not adhere to each other and ensure smooth production of end products. The selection of a specific antiblocking agent for polyethylene blends used to manufacture films can dictate overall film quality and manufacturing efficiency. Grace’s SYLOBLOC® antiblocking agents are optimized to the highest degree possible to ensure quality and efficiency.

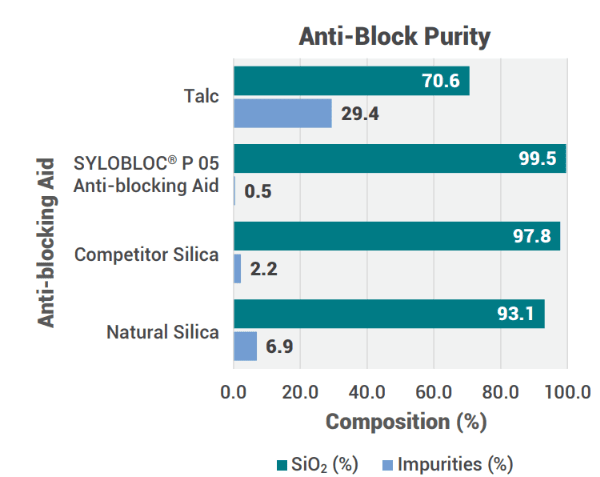

High Purity

SYLOBLOC® is a line of synthetic silica antiblocking additives with excellent optical properties and high effectiveness in plastic films at low use rates. They are among the most highly pure antiblocking agents available on the market, which creates an advantage over other types of film antiblocking agents. The data below compares SYLOBLOC® P05 to talc, natural silica, and another synthetic silica product, which are all used as antiblocking agents. As seen, SYLOBLOC® P05 is both qualitatively and quantitatively purer than the other options analyzed.

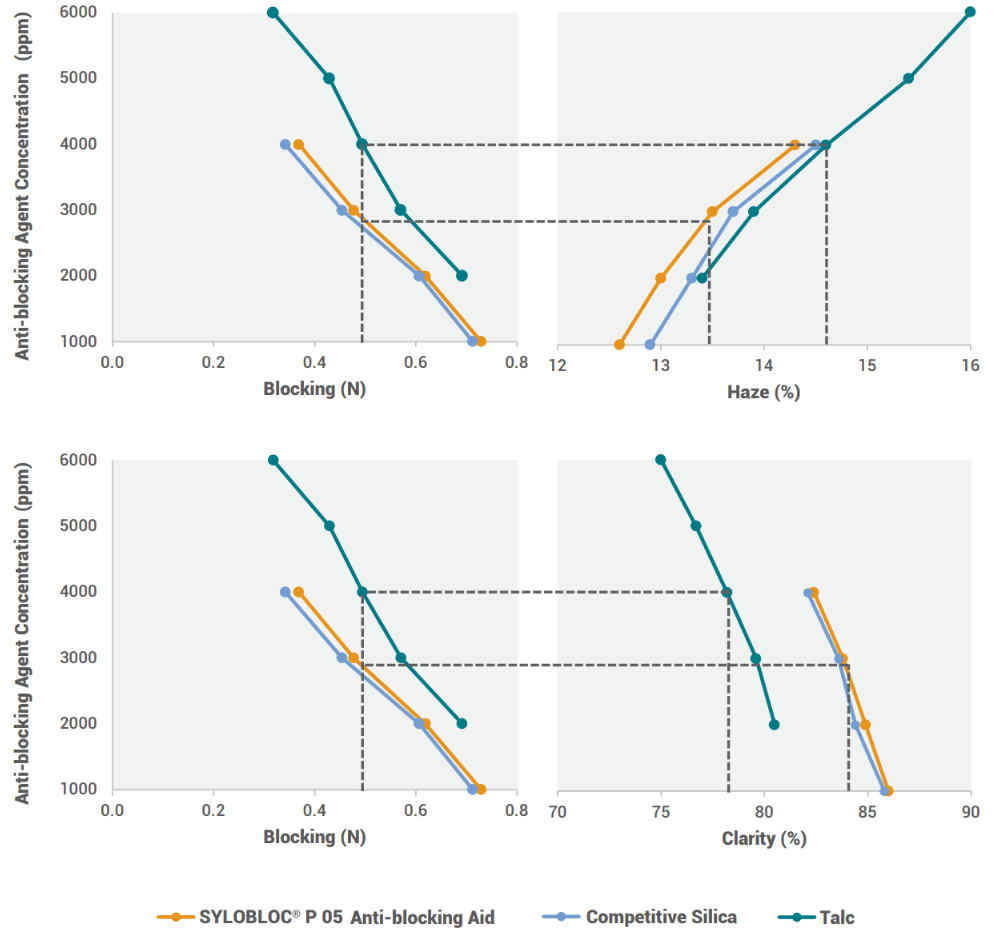

In film applications where optical clarity and aesthetics are paramount, the purity of SYLOBLOC® P05 minimizes haze and improves clarity of films. The graphs below compare SYLOBLOC® P05, talc, and a competitive silica antiblocking agent used in a 30 µm thick C4-LLDPE commercial film. While both silica antiblocking agents provided better antiblocking performance at the same concentration, SYLOBLOC® P05 provided lower haze and better clarity than the other options.

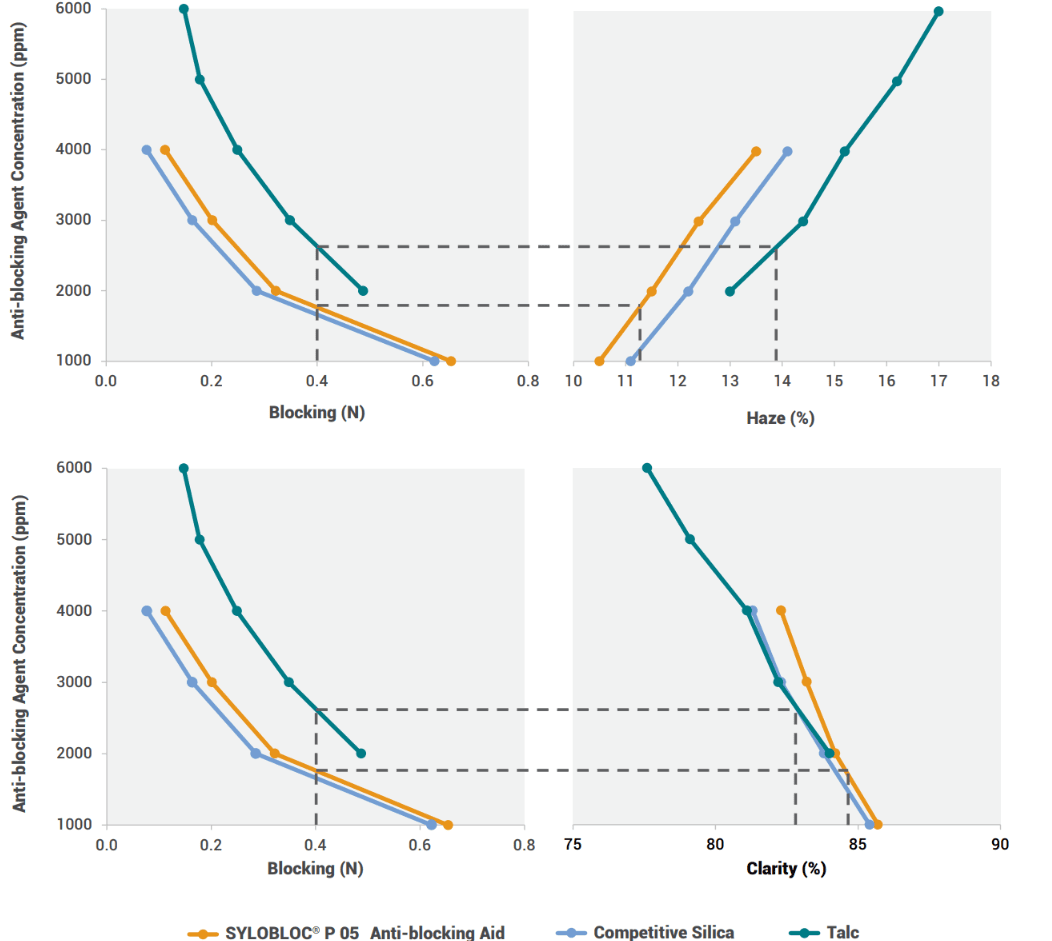

Similar results were obtained with a 30 µm thick LDPE commercial film; the graphs below indicate that SYLOBLOC® P05 had an even more pronounced reduction in film haze and improvement in optical clarity than both other options.

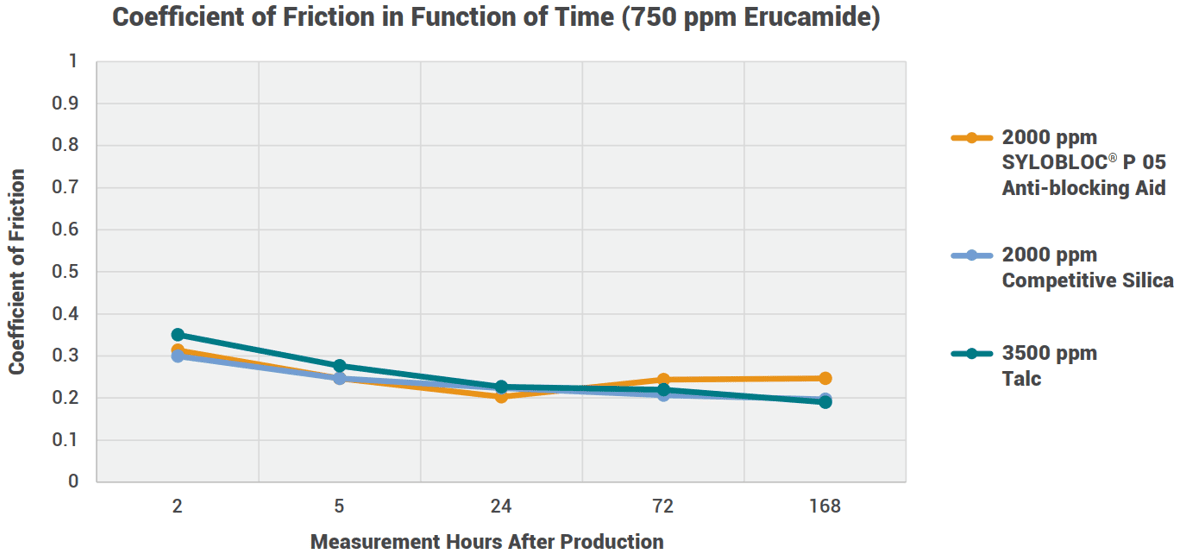

Minimal Surface Modification

In some cases, slip aids used in blends to make films may be adsorbed onto antiblocking agents, which ultimately provides a lower coefficient of friction than what may be desired. SYLOBLOC® P05 resists this effect as shown below, where an equivalent concentration of each antiblocking agent was used in conjunction with 750 ppm of erucamide in a 30 µm thick C6-LLDPE film. The results indicate that SYLOBLOC® P05 resisted the adsorption of the erucamide, maintaining a higher coefficient of friction compared to the other antiblocking agents.

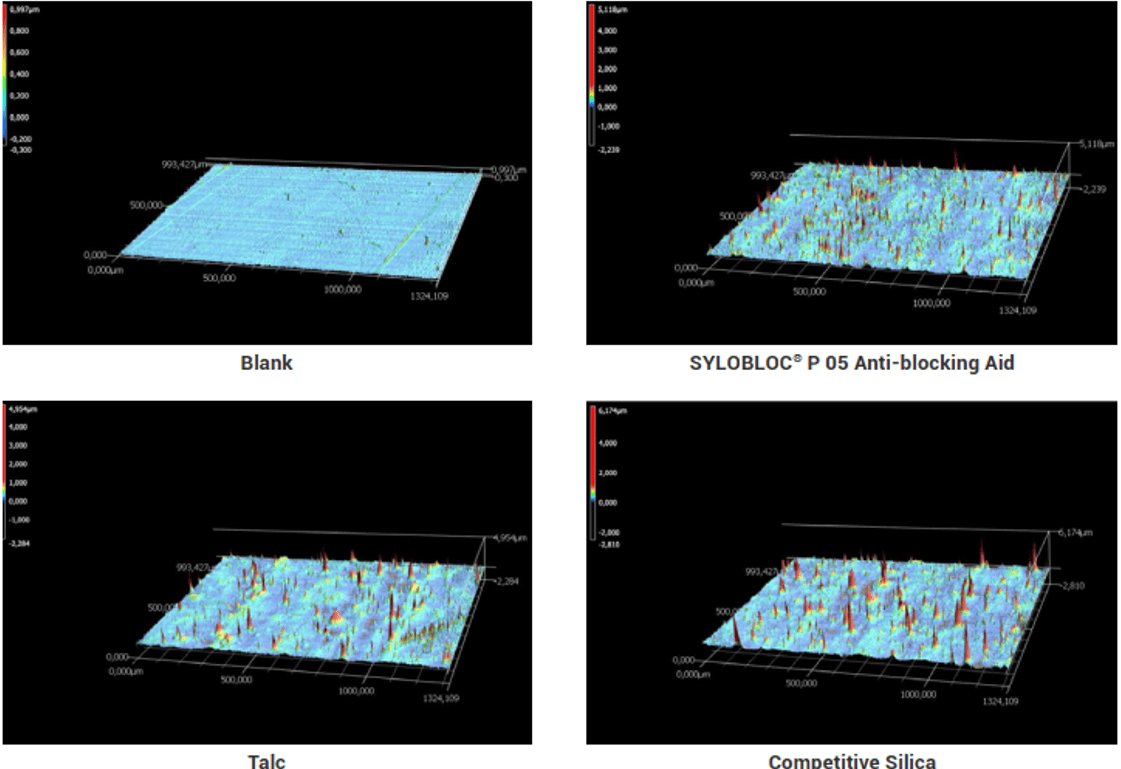

SYLOBLOC® P05 also maintains a smoother film surface, contributing to better optical properties quantified in the previous section. Below, images from a laser scanning microscope depict how smaller peaks are present on the film surface, maintaining smoothness.

Consistent Particle Size Distributions

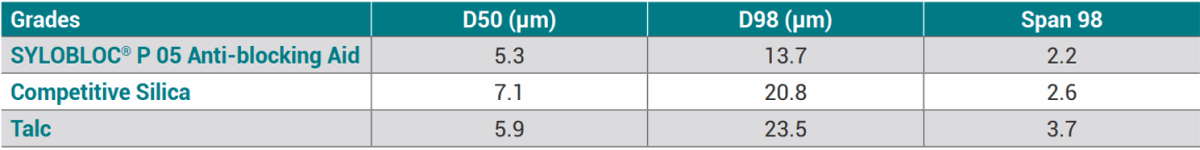

The stringent quality processes in which SYLOBLOC® is manufactured create a narrow average particle size range and size distribution that can impact film optical properties and clog masterbatch filter screens. Below, particle size data of SYLOBLOC® P05, the competitive silica, and talc indicate that SYLOBLOC® P05 has fewer coarse particles and the narrowest particle size distribution.

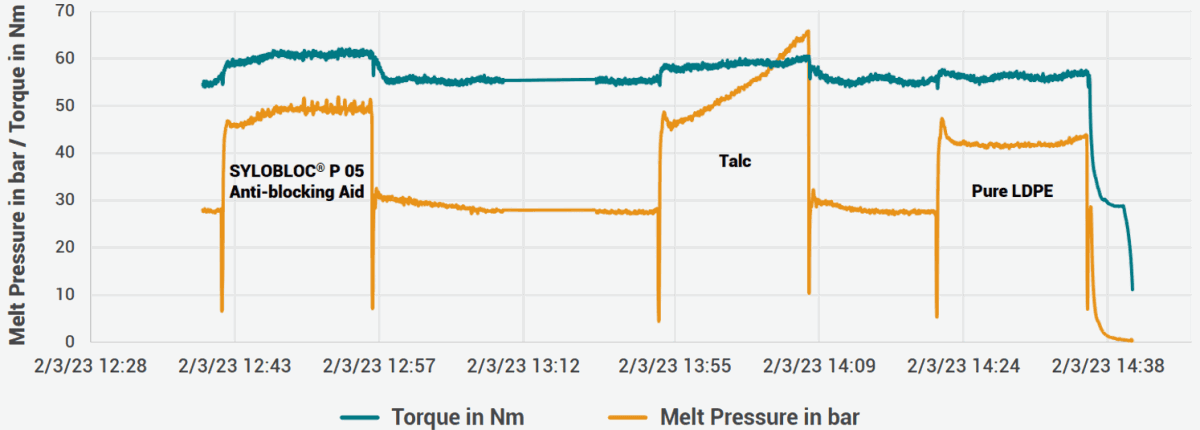

These qualities facilitate lower filter-pressure buildup during masterbatch production. The graph below indicates that melt pressure was significantly more consistent using SYLOBLOC® P05 versus talc, due to the absence of larger particles that clog filters and increase back pressure.

Summary

SYLOBLOC® P05 is a synthetic silica antiblocking agent that maximizes optical clarity and antiblocking performance in LDPE films versus other antiblocking agents. This is due to a lower level of impurities, a more consistent particle size, and a lower proportion of coarse particles. SYLOBLOC® P05 also maintains a smoother surface and resists slip-agent adsorption better than other antiblocking agents. ChemPoint is here to help answer questions and provide samples and quotes on SYLOBLOC® and any other products that polymer and resin compounders, masterbatchers, and one-pack producers need. Click below to get in touch.

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States