Select Your Region

Trilene® EPDM in Rubber Compounding

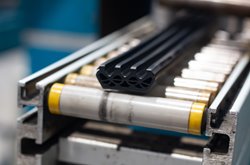

Trilene® liquid polymers are a family of low molecular weight ethylene-propylene copolymers and ethylene-propylene non-conjugated diene terpolymers. Liquid EPDM polymers are used in various rubber compounding formulations to enhance the process properties and improve the quality of molded products.

EPDM Rubber compounding has seen growth in various applications like automotive, wire and cable, roof materials, and thermoplastic vulcanizates (TPV). These applications all require a specific molecular structure and versatile processing properties provided by EPDM rubber. Traditional rubber compound applications overmolded or co-extruded EPDM rubber but face challenges to reduce the cost and weight of the final product. Trilene® liquid EPDM offers cost-saving advantages and a recyclable alternative that is easier to process. As a reactive plasticizer in high durometer EPDM that produces easily processable compounds without any significant loss of hardness, low-temperature flexibility, heat aging, ozone resistance, weatherability, and retaining sealing force.

Trilene® EPDM polymers are excellent plasticizers, chemical crosslinkers, and viscosity modifiers in various rubber, elastomer, and plastic applications. Additionally, they provide exceptional versatility, making them suitable for use in a broad range of traditional rubber curing processes alone or combined with solid elastomers. Trilene® liquid EPDM elastomers are produced with a stable saturated hydrocarbon backbone through a random polymerization process. Their reactivity is derived from pendant unsaturation, and the terpolymers provide practical crosslinking applications when required. Either used alone or with a solid elastomer, it cures conventional rubber alongside providing additional processing benefits of a liquid. Their unique chemical versatility allows them to be used in various applications and processes.

Trilene® EPDM for Rubber Compounding Applications:

- Low molecular weight allows for versatility in rubber compound application

- Liquid EPDM polymers are used to lower the viscosity of rubber formulations for improved processability

- Improved physical properties and reduced scrap

- Excellent choice for improved hardness in high durometer rubber formulations

- VOC-free and non-extractable

- Facilitates the mixing process, which reduces the overall mixing capital cost

Functionality in Rubber Compounding

Low Viscosity:

Trilene® EPDM has lower viscosity characteristics compared to traditional EPDM polymers. The low viscosity of Trilene® liquid EPDM provides lower intensity mixing requirements, which can contribute to capital savings by using less expensive mixing equipment and tools.

Reactive Plasticizer:Trilene® liquid EPDM polymers are used to substitute high molecular weight elastomer resin in many rubber compounding formulations. The EPDM polymers provide enhanced physical properties and reduced production scrap. In addition to processing benefits, Trilene® is also curable, non-extractable, and nonvolatile after cure. The addition of Trilene® at 10 phr typically lowers the Mooney viscosity of rubber compounds by 15 points.

Trilene in Molded Rubber:

Trilene® is ideal for processing automotive and general industrial rubber parts such as brake parts, o-rings, and gaskets. Lion liquid EPDM polymers can also be crosslinked through peroxide or sulfur cured, and it offers various improvements and benefits to rubber and elastomeric formulations:

- Reduced Mooney viscosity by 20-25%, compared to control

- Suitable for rubber processability analyzer (RPA) and high shear rates

- Excellent for molding, extrusion, calendaring applications

- Lower extractability compared to competitive paraffinic oils such as Sunpar 2280

- Lower volatility by thermogravimetric analysis (TGA)

- Significantly reduced cycle times and energy costs

- Complex resin shapes are attainable with better impact resistance

- Perfect fluid seals in the molding of brake rubber parts

Trilene® Properties in Molded Rubber: |

| Peroxide Cures | Sulfur Cures | |||||||

| None | T-65 | T-77 | Sunpar | None | T-67 | T-77 | Sunpar | |

| Mooney at 100ºC (212ºF) | ||||||||

| Viscosity, ML(1+4) | 83 | 64 | 69 | 63 | 92 | 72 | 73 | 69 |

| RPA Viscosity at 150ºC (302ºF) | ||||||||

| 1 rad/s, kPa-s | 71 | 54 | 60 | 51 | 78 | 58 | 58 | --- |

| 10 rad/s, kPa-s | 21 | 16 | 18 | 15 | 23 | 17 | 18 | --- |

| 100 rad/s, kPa-s | 5.3 | 4.2 | 4.5 | 3.9 | 1.8 | 4.4 | 4.5 | --- |

| ODR Rheometer at 177ºC (351ºF) | ||||||||

| ML, dN-m | 3.4 | 2.6 | 2.8 | 2.4 | 3.3 | 2.3 | 2 | 1.7 |

| MH, dN-m | 56 | 44.4 | 45 | 36.8 | 47.8 | 36.8 | 39.2 | 35.3 |

| tc50, minutes | 3.4 | 4.1 | 3.4 | 3.4 | 1.8 | 1.9 | 2.2 | 2.3 |

| tc90, minutes | 12.5 | 13.5 | 13.1 | 12.4 | 10.0 | 7.8 | 7.4 | 8 |

| Press Cured 30 minutes at 166ºC (331ºF) | ||||||||

| Hardness, Shore A | 73 | 69 | 70 | 66 | 74 | 72 | 72 | 69 |

| 200% Modulus, MPa | 13 | 9.8 | 11.5 | 4 | 10.5 | 9 | 8.7 | 8.7 |

| Tensile Strength, MPa | 19.4 | 19.2 | 19.2 | 17.6 | 15.4 | 14.4 | 14.4 | 14.9 |

| Elongation at Break, % | 270 | 310 | 280 | 460 | 340 | 360 | 310 | 400 |

| Aged 22 hours at 175ºC (347ºF) | ||||||||

| Compression Set % | 13 | 16 | 16 | 18 | 69 | 74 | 73 | 73 |

| Immersed in Chloroform/Acetone (68/32) | ||||||||

| Extract % | 1.7 | 1.8 | 1.8 | 5.8 | 3.2 | 2.8 | 3.5 | 8.4 |

| TGA for 30 minutes in Nitrogen at 232ºC (450ºF) | ||||||||

| Volatiles, % weight loss | 0.32 | 0.34 | 0.30 | 0.61 | 0.78 | 0.74 | 0.75 | 0.90 |

| Aged 70 hours at 150ºC (302ºF) | ||||||||

| Hardness, Points Change | +1 | +1 | +2 | 0 | +7 | +7 | +3 | +6 |

| Tensile, % Change | -9 | -8 | -12 | -32 | +15 | +7 | +16 | +9 |

| Elongation, % Change | -20 | 0 | -20 | -34 | -37 | -44 | -39 | 40 |

| Immersed in Brake Fluid 22 hours at 150ºC (302ºF) | ||||||||

| DOT #3 Volume Swell, % | 2.8 | 3.0 | 3.1 | 0.4 | 2.2 | 2.6 | 2.1 | 0.2 |

| DOT #4 Volume Swell, % | 2.2 | 2.0 | 1.9 | -0.9 | 1.5 | 2.1 | 2.1 | -0.9 |

Trilene® Gum Cures:

The following table shows simple formulations of Trilene® polymers and curatives mixed under a vacuum. The physical properties shown can be improved significantly by the incorporation of suitable reinforcing fillers:

Peroxide Cure

|

Resin Cure

|

Sulfur Cure

|

|

|---|---|---|---|

| Trilene® 65 | 100

|

100

|

---

|

| Trilene® 67 | ---

|

---

|

100

|

| Naugex MBTS Accelerator | 4

|

---

|

---

|

| Spider Brand Sulfur | 4

|

---

|

---

|

| DiCup R Peroxide | ---

|

2

|

---

|

| Sartomer SR-350 Coagent | ---

|

3

|

---

|

| Protox 169 Zinc Oxide | ---

|

---

|

5

|

| Stearic Aicd | ---

|

---

|

1

|

| Schenectady SP-1055 Resin | ---

|

---

|

10

|

Physical Properties: Cured 1 hour at 160ºC (320ºF) |

|||

| Hardness, Shore A | 38

|

33

|

37

|

| 100% Modulus, MPa (psi) |

0.5

(69) |

0.3

(42) |

0.7

(100) |

| Tensile Srength, mpA (psi) |

1.4

(205) |

1.2

(171) |

1.6

(235) |

| Elongation at Break, % | 287

|

233

|

230

|

Trilene® Applications:

Trilene® liquid EPDM copolymers and terpolymers are typically used to modify the flow characteristics and enhance the processing of high molecular weight elastomers, thermoplastics, and plastics.

|

Trilene® is an ideal solution to improve hardness and processing properties in high durometer rubber formulations. Replacing the conventional plasticizers with Trilene® terpolymers maximizes hardness and enhances the compounding process without compromising physical properties or compression set. |

|

High Durometer Rubber Compounding with Trilene® |

A

|

B

|

C

|

D

|

|

|---|---|---|---|---|

| Plasticizer (full recipe below) | ||||

| Paraffinic oil | 25

|

45

|

25

|

25

|

| Trilene® 65 | ---

|

---

|

20

|

30

|

| Processing | ||||

| Mooney ML 1+4 @ 100°C | >200

|

86

|

92

|

75

|

| Unaged Properties | ||||

| Shore A Hardness | 86

|

78

|

81

|

81

|

| Compression set (22hrs@70C) % | 9

|

9

|

9

|

9

|

| Die C Tear kN/m | 21.40

|

20.70

|

20.80

|

24.00

|

| Ultimate Tensile Mpa | 12.60

|

12.40

|

12.70

|

12.90

|

| Ultimate Elongation % | 100

|

140

|

120

|

130

|

Recipe: 100phr High MW EPDM polymer, 140phr N-785 black, Plasticizer variable, Stearic acid - 1phr, Zinc oxide - 5phr, PE wax - 10phr, TAC (72%) 2.8phr, CaO (80) - 5phr, Di-(t-butylperoxy-i-propyl) benzene(60%) - 3.3phr

Effect of Plasticizer on Hardness |

None

|

Oil

|

|||

|---|---|---|---|---|

| Plasticizer (full recipe below) | ||||

| Paraffinic oil | ---

|

10

|

---

|

---

|

| Trilene® 65 | ---

|

---

|

10

|

---

|

| Trilene® 77 | ---

|

---

|

---

|

10

|

| Processing | ||||

| Mooney ML 1+4 @ 100°C | 83

|

63

|

64

|

69

|

| Unaged Properties | ||||

| Shore A Hardness | 73

|

66

|

69

|

70

|

| 100% Modulus Mpa | 4.60

|

1.65

|

3.34

|

4.00

|

| Ultimate Tensile Mpa | 19.40

|

17.60

|

19.20

|

19.20

|

| Ultimate Elongation % | 12.60

|

460

|

310

|

280

|

Recipe: 100phr High MW EPDM polymer, 60phr N-774 black, Plasticizer variable, Zinc oxide - 5phr, TMQ - 1phr, TMTM - 2phr, Dicumyl Peroxide (40%) - 7phr

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States