Applications

Select Your Region

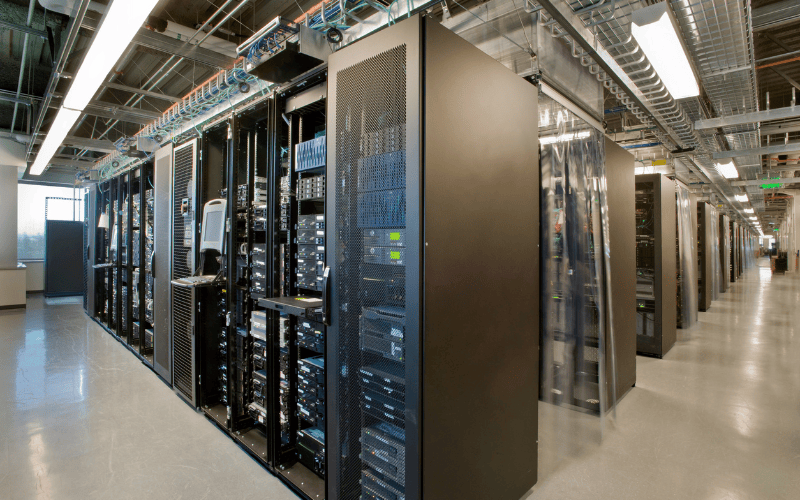

AI data centers generate substantial heat due to high-density computing. Viton™ fluoroelastomers exhibit outstanding thermal resistance, maintaining their sealing and elasticity properties at continuous temperatures up to 204°C (399°F) and withstanding excursions up to 315°C (599°F). This thermal stability ensures that seals, gaskets, and O-rings remain effective, reducing the risk of thermal degradation and system failures.

Modern data centers employ various cooling methods, including liquid cooling systems that utilize aggressive fluids. Viton™ fluoroelastomers demonstrate broad chemical compatibility, resisting degradation from coolants, hydrocarbons, dielectric fluids, lubricants, and other harsh chemicals commonly found in data center environments. Chemical resistance extends the lifespan of critical components and minimizes maintenance requirements.

Applications

AI data servers operate extremely hot, so liquid or immersion cooling systems are vital to maintain computing integrity. Viton™ FKM are used in the following:

Seals and O-rings in liquid-cooled cold plates and manifolds

O-rings, gaskets, quick-connect seals, pump diaphragms

Gaskets in heat exchangers, chillers, and closed-loop systems

Tubing connectors and valves exposed to glycol–water mixtures or dielectric coolants

Pump housings and mechanical seals where coolant exposure and high temperatures are constant

Viton™ is essential in backup power infrastructure where exposure to lubricants, fuels, and heat occurs.

Gaskets and seals in generator enclosures and battery systems

Diaphragms and isolators for fuel systems in diesel generators

Bushings and cable seals in electrical enclosures to prevent ingress of dust, moisture, and coolant

Generator gaskets, fuel system seals, and battery housing grommets

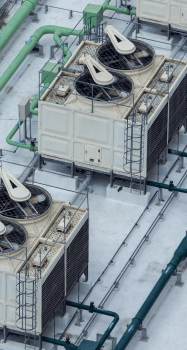

Data center infrastructure requires maintaining optimal airflow and contamination control.

Seals for ducting systems and environmental enclosures

Elastomeric vibration isolators for equipment racks and floor systems

Duct seals, vibration isolators, and weatherproof enclosures

Expansion joints and weatherproof gaskets for outdoor cooling towers

Even at the microlevel, Viton™ can be used in the following:

Enclosure door seals for thermal insulation

Fire-suppression system valves and tubing seals (especially for systems using chemical agents)

Elastomeric seals resistant to fluorinated and hydrocarbon fluids

Rack enclosures, EMI shielding gaskets, connector seals, cable penetrations, and equipment seals

Conclusion

Viton™ fluoroelastomers (FKM) are backed by decades of performance with industry-proven reliability in aerospace, automotive, and oil and gas exploration. Click below to talk to a technical expert today about which grade of Viton™ will work best for your application!

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States