Select Your Region

BIOBAN™ BTCM preservative for tape joint compounds

Tape joint compounds are one of the most challenging building materials to preserve and protect from microbial contamination.

Formulators used formaldehyde-releasing chemistries (FAR) for ages to provide the required level of protection and prevent viscosity drops over time. The drastic viscosity drops occur as a result of microbial contamination and degradation of organic compounds over time.

The good news, formaldehyde-releasing biocides are no longer the only effective option for your tape joints and sealant formulations.

Evaluations of BIOBAN™ BTCM, the new dual-active preservative from LANXESS, formerly manufactured by DuPont, demonstrated excellent antimicrobial efficacy and provided advanced in-can protection to tape joint formulations against bacteria and fungi while retaining the desired viscosity over time.

BIOBAN™ BTCM is a dual-active in-can preservative that is based on a combination of two active ingredients, Benzisothiazolinone (BIT) and Methylchloroisothiazolinone / Methylisothiazolinone (CMIT/MIT). It provides both short and long-term preservation for ultimate protection and enhanced formulation flexibility.

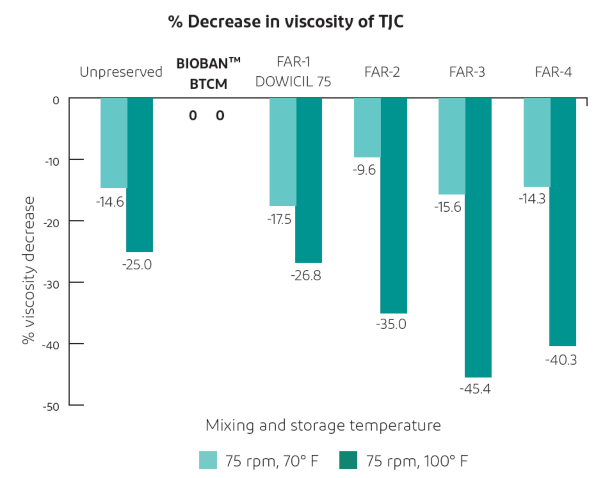

A 12-week study was conducted, tracking viscosity changes in tape joint compound samples treated with four different formaldehyde-releasing preservatives. In addition, BIOBAN™ BTCM preservative and an unpreserved control sample were evaluated at multiple concentrations.

Testing Results: Samples preserved with formaldehyde-releasing preservatives showed significant drops in viscosity ranging from 9.6% to 45.4%. In contrast, the tape joint compound treated with BIOBAN™ BTCM or the BIT/CMIT/MIT blend at various concentrations did not experience any decreases in viscosity.

Conclusion: Samples treated with BIOBAN™ BTCM did not exhibit viscosity changes

BIOBAN™ BTCM concentrations evaluated were 2,000, 3,000, and 4,000 ppm of the product as supplied.

Percentages of viscosity decreases (Brabender Unit) were observed over 12 weeks in a tape joint compound formulation treated with various preservative products.

Each preservative was evaluated at multiple concentrations across the EPA-approved use range. Percentages of viscosity decrease are averages of the data collected for each sample by comparing time zero- and 12-week data. Time zero occurred within 24 hours of the preservative addition, so any immediate changes in viscosity changes that occurred in less than 24 hours were not recorded.

The good news, formaldehyde-releasing biocides are no longer the only effective option for your tape joints and sealant formulations.

Evaluations of BIOBAN™ BTCM, the new dual-active preservative from LANXESS, formerly manufactured by DuPont, demonstrated excellent antimicrobial efficacy and provided advanced in-can protection to tape joint formulations against bacteria and fungi while retaining the desired viscosity over time.

BIOBAN™ BTCM is a dual-active in-can preservative that is based on a combination of two active ingredients, Benzisothiazolinone (BIT) and Methylchloroisothiazolinone / Methylisothiazolinone (CMIT/MIT). It provides both short and long-term preservation for ultimate protection and enhanced formulation flexibility.

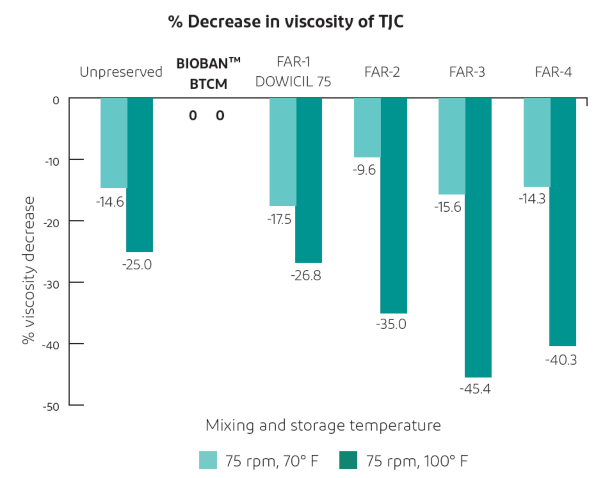

A 12-week study was conducted, tracking viscosity changes in tape joint compound samples treated with four different formaldehyde-releasing preservatives. In addition, BIOBAN™ BTCM preservative and an unpreserved control sample were evaluated at multiple concentrations.

Testing Results: Samples preserved with formaldehyde-releasing preservatives showed significant drops in viscosity ranging from 9.6% to 45.4%. In contrast, the tape joint compound treated with BIOBAN™ BTCM or the BIT/CMIT/MIT blend at various concentrations did not experience any decreases in viscosity.

Conclusion: Samples treated with BIOBAN™ BTCM did not exhibit viscosity changes

BIOBAN™ BTCM concentrations evaluated were 2,000, 3,000, and 4,000 ppm of the product as supplied.

Percentages of viscosity decreases (Brabender Unit) were observed over 12 weeks in a tape joint compound formulation treated with various preservative products.

Each preservative was evaluated at multiple concentrations across the EPA-approved use range. Percentages of viscosity decrease are averages of the data collected for each sample by comparing time zero- and 12-week data. Time zero occurred within 24 hours of the preservative addition, so any immediate changes in viscosity changes that occurred in less than 24 hours were not recorded.

It's time to change the preservative in your tape joints and challenging building material formulations

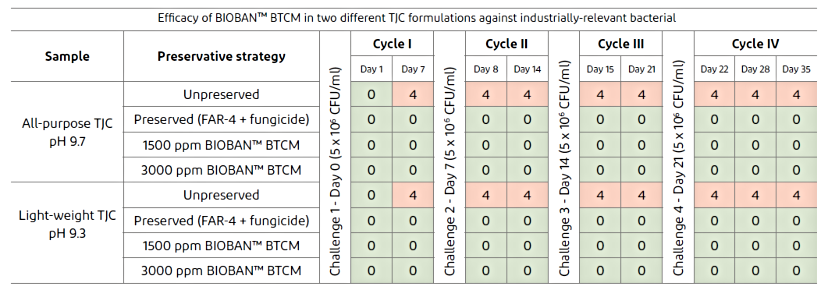

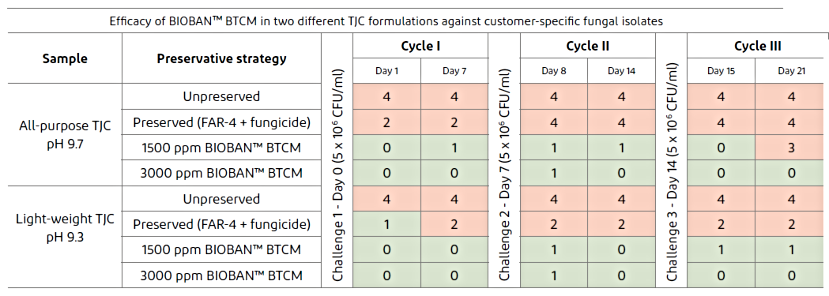

The antimicrobial efficacy of BIOBAN™ BTCM was evaluated in two commercially available joint compounds, an all-purpose formulation (pH 9.7) and a lightweight formulation (pH 9.3).

Unpreserved samples of each tape joint compound formulation were also tested along with samples dosed with BIOBAN™ BTCM. Samples were challenged four times over 35 days with industrially relevant strains of bacteria. The second set of samples was challenged with customer-specific fungal contaminants three times over 21 days.

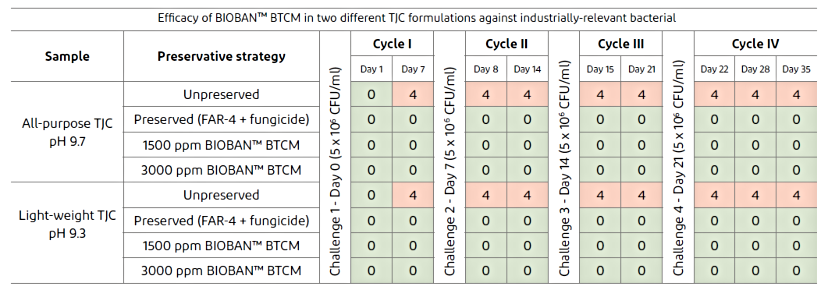

Unpreserved samples of each tape joint compound formulation were also tested along with samples dosed with BIOBAN™ BTCM. Samples were challenged four times over 35 days with industrially relevant strains of bacteria. The second set of samples was challenged with customer-specific fungal contaminants three times over 21 days.

BIOBAN™ BTCM delivers equivalent performance to combinations of FAR + fungicide against industry-relevant bacterial strains

Growth is scored from 0 to 4, with scores of 0 to 1 as passing scores. A score of 1 is indicative of 1 x 101 to 9 x 101 colony forming units (CFU/mL).

Industrially relevant bacteria evaluated included: Pseudomonas aeruginosa ATCC# 15442, Pseudomonas aeruginosa ATCC# 10145, Enterobacter aerogenes ATCC# 13048, Alcaligenes faecalis ATCC# 8750, Pseudomonas fluorescens ATCC# 17397, Staphylococcus aureus ATCC# 6538.

TJC samples were inoculated four times over 35 days. The surviving bacterial population (colonies) was enumerated 24 hours and seven days post-inoculation.

Industrially relevant bacteria evaluated included: Pseudomonas aeruginosa ATCC# 15442, Pseudomonas aeruginosa ATCC# 10145, Enterobacter aerogenes ATCC# 13048, Alcaligenes faecalis ATCC# 8750, Pseudomonas fluorescens ATCC# 17397, Staphylococcus aureus ATCC# 6538.

TJC samples were inoculated four times over 35 days. The surviving bacterial population (colonies) was enumerated 24 hours and seven days post-inoculation.

BIOBAN™ BTCM outperformed a combination of FAR + fungicide blend when challenge tested against customer-specific fungal isolates

Customer-specific isolates from contaminated TJC products included yeast. TJC samples were inoculated three times over 21 days. The surviving fungal population (colonies) was enumerated 24 hours and 7 days post-inoculation. Scores of 0 to 1 are passing scores. A score of 1 is indicative of 1 x 101 to 9 x 101 CFU/mL.

Contact us today to request your sample of BIOBAN™ BTCM.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States