Select Your Region

Viton™ FKM for Semiconductor Fabrication

|

|

| Superior Performance |

Chemours Viton™ Fluoroelastomers play a pivotal role in enhancing the efficiency and reliability of semiconductor manufacturers operations. One key advantage of Viton™ Fluoroelastomers in semiconductor manufacturing is their resistance to a wide range of aggressive chemicals commonly used in the industry. The harsh chemical environments inherent in semiconductor wafer fabrication processes, such as etching, deposition, and cleaning, demand materials that can withstand prolonged exposure without compromising their structural integrity. Viton™ Fluoroelastomers excel in this regard, providing a reliable barrier against corrosive substances, thereby extending the lifespan of critical components and reducing maintenance requirements.

The superior thermal stability of Viton™ Fluoroelastomers is instrumental in semiconductor manufacturing operations with elevated temperatures. These elastomers can endure extreme heat conditions without undergoing significant degradation or loss of physical properties. This thermal resilience ensures the consistent performance of equipment and seals, contributing to the overall stability and repeatability in semiconductor fabrication.

Furthermore, the mechanical durability aspect offers molded FKM elastomers excellent tensile strength, tear resistance, and flexiblity in molded fluoroelastomer parts. These properties make Viton™ Fluoroelastomers ideal for use as seals, gaskets, O-rings and more in semiconductor equipment. This mechanical robustness enhances the reliability of sterile conditions, minimizing the risk of leaks and contamination that could adversely impact operations.

| Viton™ Benefits for Semiconductor Fabrication |

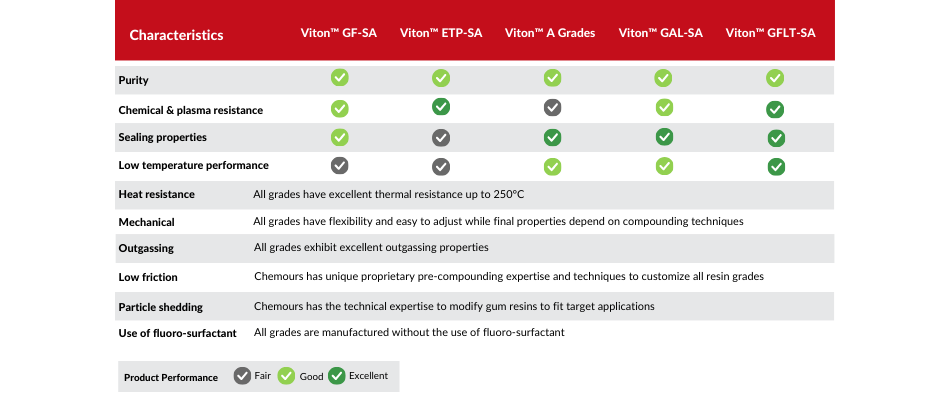

Below are some unique benefits that Viton™ fluorolastomers offer to both wet and dry semiconductor production processes in response to the industry's strict requirements.

- Minimal metallic ion content

- Contaminant elimination

- Compatibility with a variety of rubber molding processes and intricate shapes

- Chemical and plasma resistance

- Superior reliability and repeatability

- Low particle generation

- High dimensional stability

- Thermal stability

- Low outgassing

- Compression set resistance

- Mechanical strength

- Wide temperature range

- Seal bonding integrity

- Hydrophobic

| Viton™ Application Mix |

| FKM Semiconductor Applications |

Semiconductor wafer processing requires resistance to both wet and dry fabrication chemistries, such as etching, ashing, stripping, copper plating, and chemical vapor deposition.

Wet Process Applications

This process for semiconductor wafer manufacturing requires continued midrange operating temperatures with exposure to ultrapure deionized water and low levels of extractable total organic carbon.

| FKM in Semiconductor Fabrication Wet Etch Processes |

- O-rings in the process chamber spinner

- Chemical cabinet tank seals

- Wet-station door gaskets

- Filter cartridges PFA or FEP encapsulated FKM

- Exhaust system diaphragms

Dry Process Fabrication

Between chemical and physical etching processes, dry processing removes selected areas from the surface layer and requires extreme operating reliability for semiconductor equipment components.

| FKM in Semiconductor Fabrication Dry Processes |

- Chamber, gate, and valve seals

- Exhaust sysemt

- Vaccum seals

- Piping seals

- O-rings for vacuum pump

| FKM in Auxiliary Processes |

- O-ring regulators

- Pneumatic control equipment

- Photoresistant manufacturing

In conclusion, the value properties of Viton™ Fluoroelastomers, encompassing chemical resistance, thermal stability, low outgassing, compression set resistance, mechanical strength, wide temperature range, and hydrophobicity, collectively contribute to their indispensable role in semiconductor manufacturing. These properties not only enhance the reliability and performance of critical components but also align with stringent demands for the semiconductor industry for precision, cleanliness, and efficiency.

Viton™ fluoroelastomers and any associated logo is a trademark or copyright of THE CHEMOURS COMPANY FC, LLC used with consent by ChemPoint, an authorized distributor of THE CHEMOURS COMPANY FC, LLC.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States