Select Your Region

Why Datacenter MRO is Different

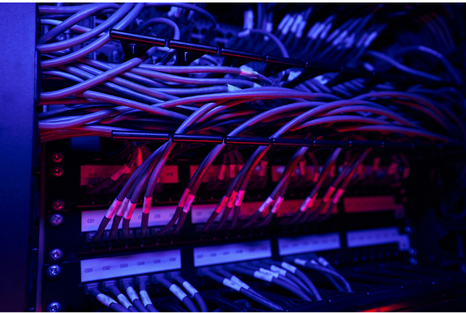

Today’s hyperscale and edge data centers pack more compute into every rack, driving heat loads past 50 kW per rack and forcing 24/7 mechanical systems to run on a razor-thin margin of error. If coolant fouls, a fan bearing fails, or a compressor seizes, a single breakdown can push outlet temperatures above ASHRAE limits in minutes—risking costly downtime for large operators. The core challenge: keeping critical components cool, clean, sealed, and lubricated without interrupting live traffic. Moreover, with such dense compute environments and increased power consumption, even minor inefficiencies in heat transfer or lubrication can escalate rapidly, leading to increased risk of hardware degradation or catastrophic failure. Therefore, proactive and predictive maintenance strategies using advanced materials have become essential to ensure reliability and efficiencies in cooling and electrical sub-systems. ChemPoint’s specialty portfolio—Krytox™, MOLYKOTE®, DOWFROST™ LC, Anderol®, UCON™, and high performance plastics additives—equips maintenance teams to meet those demands with fewer interventions and longer mean time between failures.

Core Benefits— Six Ways We Extend Uptime

Ultrastable lubrication for high RPM electronics cooling fans – Krytox™ PFPE greases remain inert, nonflammable, and effective up to 400°C, eliminating carbon buildup and doubling relube intervals in fan and UPS motor bearings.

Dielectric sealing and Oring protection – MOLYKOTE® silicone compounds (e.g., 111) provide high dielectric strength (~320 V mil1) and water resistance, preventing leaks around coldplate fittings, sensor housings, and cable penetrations.

Corrosion free liquid cooling loops – DOWFROST™ LC 25% propylene glycol coolant is purpose formulated for direct-to-chip loops, shielding high surface area copper from pitting while maintaining low electrical conductivity.

Energy efficient compressor and blower oils – Anderol® synthetic diester and esterbased oils survive 10 000 h+ service, shed water, and cut chiller power draw by up to 3%.

Versatile PAG fluids for hydraulics and heat transfer – UCON™ 500 and EHC 846 fluids deliver high oxidative stability and nonflammability for racklift hydraulics, generator platens, and auxiliary cooling skids.

Plastic and elastomer additives for seals, gaskets, and cable management – Specialty ingredients improve chemical resistance, reduce outgassing, and lengthen service life in tighttolerance enclosures.

Applications & Use Cases

Cooling Loops – Direct to chip cold plates and reardoor heat exchangers (DOWFROST™ LC)

Air Handling and Fans – EC fans, CRAH/CRAC units, UPS blowers (Krytox™ GPL/XHT)

Seals, Sensors and Connectors – Orings, valve stems, electrical connectors (MOLYKOTE® and Krytox™ GPL)

Compressors and Vacuum Pumps – Central chillers, drypump systems (Anderol® 500, 1200 N)

Hydraulics and Motion – Rackelevation lifters, bypass control valves (UCON™ fluids)

Enclosure Materials – Cable jackets, wire insulation, gasket materials (plastic and lubricant additives)

Supporting Data & Validation

Specs

|

Krytox™

|

MOLYKOTE®

|

DOWFROST™ LC

|

Anderol®

|

UCON™ 500

|

Impact on Uptime

|

|---|---|---|---|---|---|---|

Operating Temp (°C)

|

−30 to 400

|

−40 to 200

|

−40 to 120

|

−40 to 230

|

−40 to 250

|

Covers full data center envelope

|

Service Life

|

2x–3x mineral grease

|

1x–2x std silicone

|

5 yr fluid life

|

10,000h+ oil drain

|

20,000h fluid life

|

Fewer planned outages

|

Conductivity/

Flammability |

nonflammable

|

High dielectric

|

Low κ (<2 µS cm1)

|

High flash point of >260°C

|

Reduces fire & arc risk

|

|

Corrosion Control

|

Chemically inert

|

Water & solvent resistant

|

Multimetal inhibitor

|

Water separation <200 ppm

|

Excellent oxidative stability

|

Prevents leaks & fouling

|

*With routine fluid analysis (oil/grease spectroscopy or coolant pH/EC checks). Data per manufacturer technical sheets.

ChemPoint Advantage — One partner, one PO, and multiple specialty chemistries engineered to keep your racks running and your SLA penalties at zero.

Keep Your Servers Cool & Your CFO Cooler

Reach out to our team via email or fill out a form on our website to book a reliability audit to benchmark current lube, seal, and coolant performance.ChemPoint Advantage — One partner, one PO, and multiple specialty chemistries engineered to keep your racks running and your SLA penalties at zero.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States