About Citroflex™ from Aurorium

Aurorium is the leader in specialty chemicals that prides itself on being a Responsible Care® company for various consumer goods, agriculture, nutrition, fine chemicals, personal care, pharmaceutical, plastic, coatings, and industrial markets. As a lead supplier of natural-based citric acid esters in North America, Aurorium has the proprietary chemistry for sizing and coalescing agents that improve coating formulations.

Citroflex™ is a range of citric acid esters from Aurorium with multiple functionalities and performance benefits for polymer systems. Citroflex™ products are commonly known as plasticizers and plastics additives, but they are also very effective coalescing agents used in paints and coating formulations.

What is a Coalescing Agent?

A coalescing agent's primary role is to soften the polymer, allowing a solid uniform continuous film as the paint dries. They are stabilizers or temporary plasticizers that provide an even dispersion for polymer or resin. Coalescing agents help form polymeric films at ambient temperatures and stabilize the coating when the water or solvent evaporates.

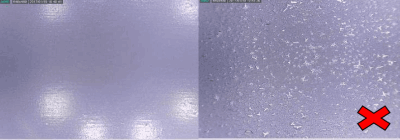

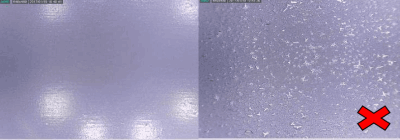

| Leneta Card |

Aluminum Panel |

|

|

Why Citroflex™ Citric Acid Esters?

These natural citric acid esters provide excellent performance in coating and paint formulation used as a phthalate-free alternative to many other plasticizers. As bio-based raw materials, Citroflex™ Citric Acid Esters are biodegradable from microorganisms in the soil. They are non-VOCs (volatile organic compounds) and non-HAP (Hazardous Air Pollutant) that efficiently combine plasticization of polymers with both hydrophilic and lipophilic properties, low order of toxicity, and rapid biodegradability.

Criteria for selecting a Coalescent Agent

Compatibility

- The coalescent agent additives must be compatible with the base polymer of the paint or the coating formulation.

Efficiency

- Coalescent agents additives are used to decrease the MFFT of the polymer-coalescent system. The coalescing aid is selected based on the base polymer glass-transition (Tg) temperature, which defines the baseline minimum film formation temperature (MFFT).

Evaporation Rate

- Coalescent agent additives with low evaporation rates are more effective coalescents, especially in formulations of water-based and low VOC coatings.

Water and Polymer Solubility Balance

- It is vital to select a coalescent agent with low water solubility and high polymer solubility. The optimal solubility ensures the film formation stability and prevents the coalescent from evaporating with the solvent (water).

Why Citroflex™ Coalescing Agents for Your Paints and Coatings

- Low evaporation rate and Low VOC of < 0.5%

- Exceptional efficacy in Tg recovery

- Excellent hardness development and superior anti-blocking properties

- Broad compatibility with polymers, binders, and a variety of substrates

- Resistance to dirt pick-up and staining for paints and coatings

- Citroflex™ offers both hydrophilic and lipophilic esters

- Nontoxic and Eco Complaint: not classified as VOC material in Europe (1999/13/EC) and 2004/42/CE) and not as HAP in the U.S. (Clean Air Act 1990)

|

|