Select Your Region

Improve Strength of PCR Polycarbonate Resins

Many industries push toward circular economy initiatives and postconsumer recycled (PCR) plastics, manufacturers face challenges in maintaining impact strength, durability, and processability in recycled polymers due to processability and degradation difficulties. Dow’s PARALOID™ Impact Modifiers provide enhanced mechanical properties to PCR polycarbonate (PC), PC/ABS, PC/PET, and other engineered resins, ensuring high-performance recyclability without compromising quality.

Challenges for Recycled Polycarbonate Resins

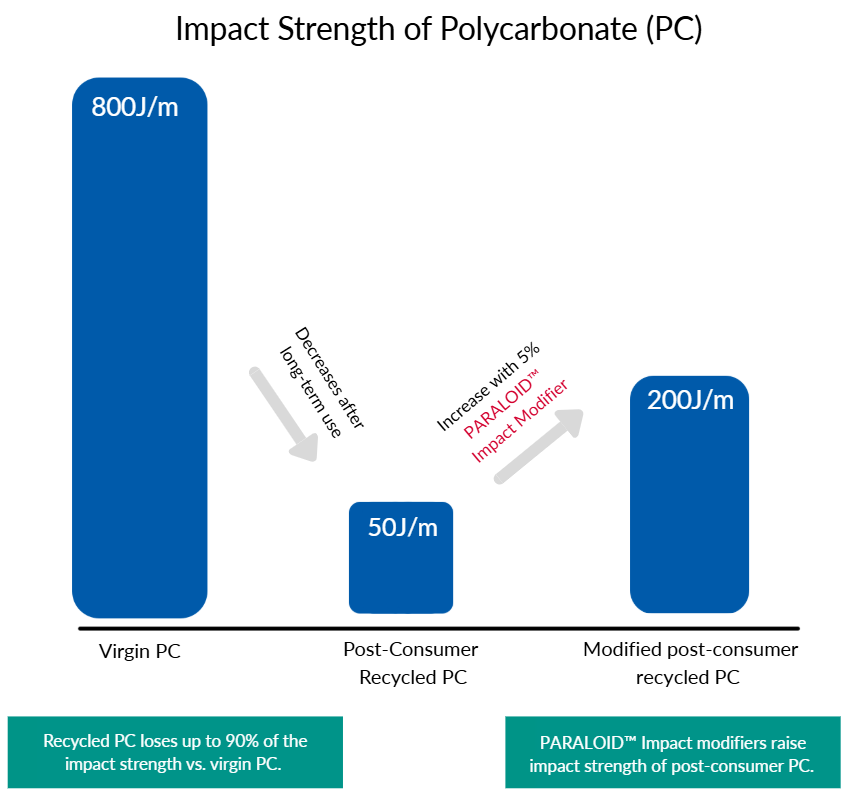

Challenge #1: Impact strength loss after long-term use

Recycled polycarbonate often struggles from reduced impact strength due to polymer degrdation and mechancial recycling processes.

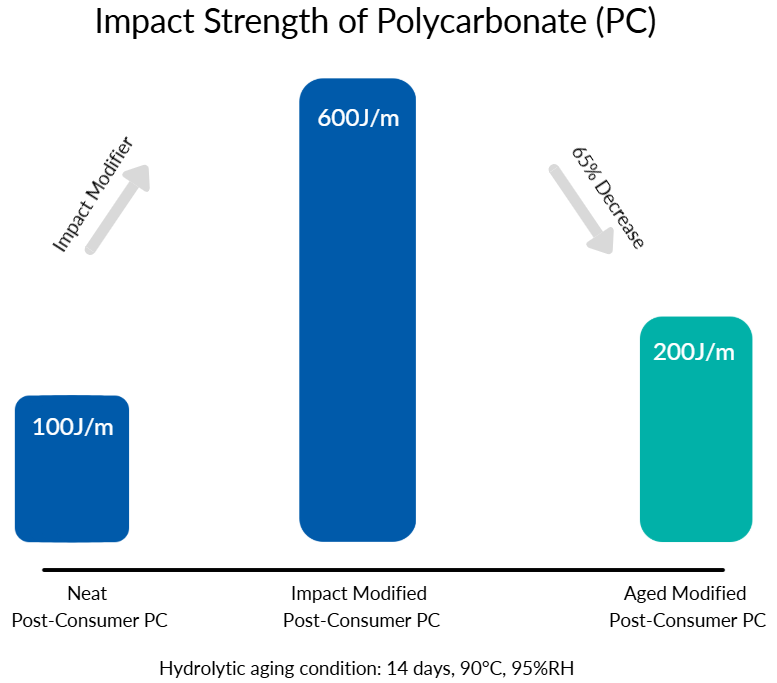

Challenge #2: Impact strength loss after hydrolytic aging

Compared to virgin materials, recycled engineer resins such as polycarbonate experience significant strength loss after it has been hydrolytically aged.

Challenge #3: Source variability of recycled polycarbonate

Recycled polycarbonate may also experience multiple processing cycle instability, which ultimately affect the long-term material integrity.

Key Benefits of PARALOID™ Impact Modifiers in Recycled Polycarbonate Resins

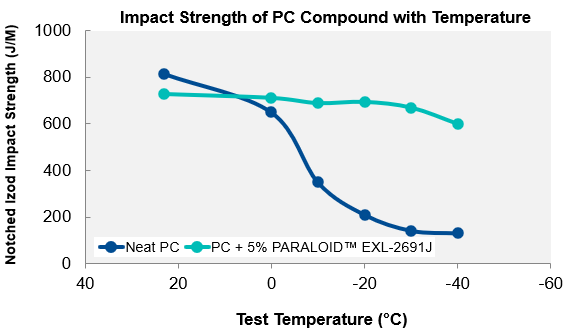

Benefit #1: Retains impact strength over a wide temperature range

Recycled polycarbonate have 82% impact retention over a 55°C temp range with PARALOID™ EXL-2691J.Typical values, not to be construed as specifications. Users should confirm results by their own tests.

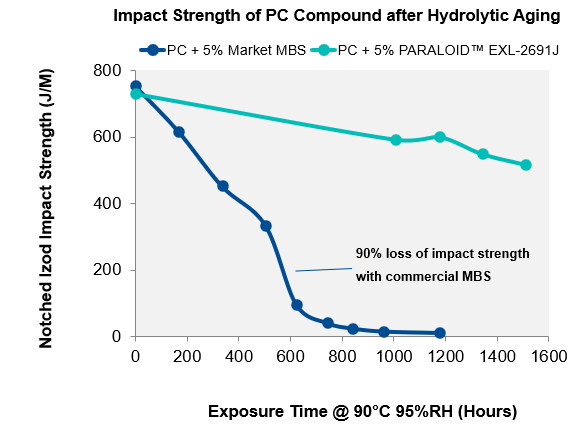

Benefit #2: Enhances hydrolysis resistance of PC formulations

Polycarbonate with PARALOID™ EXL-2691J retains 80% impact strength over 1200 hours after hydrolysis aging.Typical values, not to be construed as specifications. Users should confirm results by their own tests.

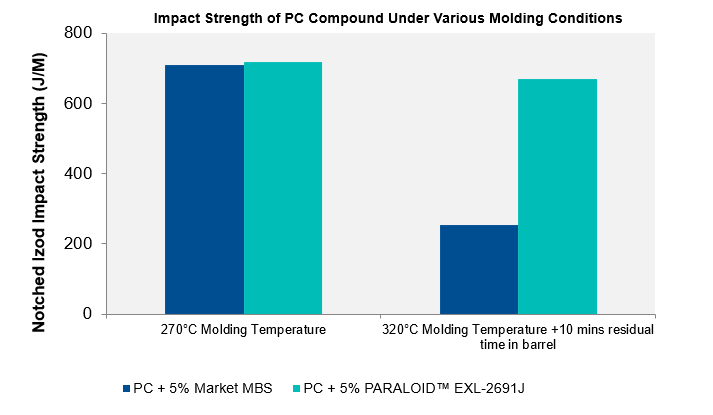

Benefit #3: Excellent processing stability for injection molding

Polycarbonate formulations with PARALOID™ EXL-2691J retains high impact strenth even at 320°C mold temperatures.

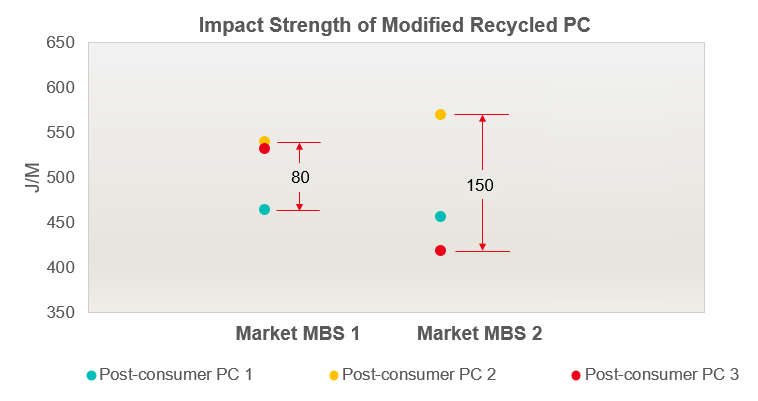

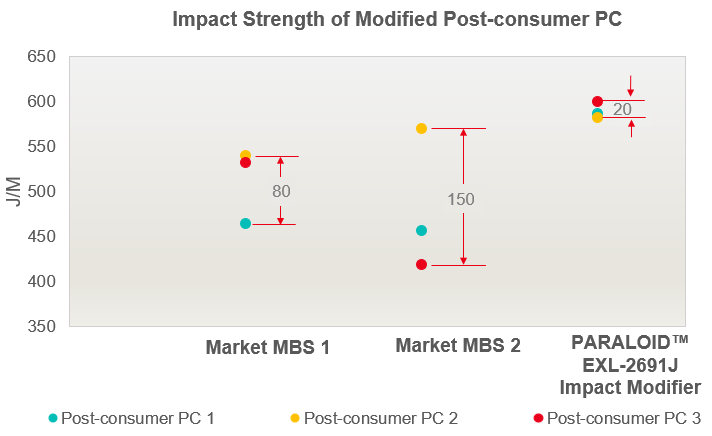

Benefit #4: Consistent performance and stability

PARALOID™ EXL-2691J exhibits less variation in impact strengthed compared to commercial MBS.

Typical values, not to be construed as specifications. Users should confirm results by their own tests.

Improved Processing Stability & Recyclability

- Optimized melt flow properties for improved processing efficiency

- Allows PCR resins to be reused in multiple cycles without degradation

- Compatibility for those manufacturers who extrude, injection mold, or process films

Superior Weatherability for Outdoor & High-Performance Applications

Acrylic-based PARALOID™ EXL-2691J Impact Modifiers provides UV resistance and color retention, making them ideal for automotive, construction, and electronics applications. These impact modifiers maintain structural integrity in varying temperatures, ensuring long-term durability.Versatility Across Engineered Resin Formulations

PARALOID™ Impact Modifiers are compatible with a variety of engineered resins, making them a flexible solution for PCR material development.Formulation Compatibility:

- PCR Polycarbonate (PC) – Toughness and durability boost

- PCR PC/ABS and PC/PET – Enhanced impact strength and stability

- High-performance plastics for electronics and automotive – Long-term weatherability

Sustainable Innovation for a Circular Economy

With rising regulatory demands and brand sustainability goals, the need for high-performance recycled plastics has never been greater. Dow’s PARALOID™ Impact Modifier technology helps manufacturers meet sustainability targets while ensuring PCR resins maintain structural integrity, durability, and performance.

Ready to Improve Your PCR Resin Performance?

Click to talk to a technical specialist today about how PARALOID™ Impact Modifiers can help optimize your recycled PCR-engineered resin formulations.PARALOID and the DOW Diamond are trademarks of The Dow Chemical Company ("Dow") or an affiliated company of Dow.

NOTICE: No freedom from infringement of any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for determining whether products and the information in this document are appropriate for Customer's use and for ensuring that Customer's workplace and disposal practices are in compliance with applicable laws and other government enactments. The product shown in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made may not have been approved for use in all countries. Dow assumes no obligation or liability for the information in this document. References to “Dow” or the “Company” mean the Dow legal entity selling the products to Customer unless otherwise expressly noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States