Select Your Region

Resins for Repulpable Hot-Melt Adhesives

|

Hot-melt adhesives are among the most widely used adhesives because they are fast curing, easy to apply, and offer environmental benefits since they emit no or relatively low VOCs. For these reasons, they are mainstays in manufacturing paper-based packaging, where they are major components used to construct containers, bags, cartons, and other shapes. |

Traditional versus Repulpable Hot-Melt Adhesives

The highest-performing hot-melt adhesives for packaging must form strong bonds, have good workable viscosities, and exhibit good resistance to shear and peel forces at elevated temperatures. While many hot-melt adhesives on the market meet these requirements, few also promote sustainability like repulpable hot-melt adhesives do. Paper is easily recyclable through the repulping processes, so the adhesives that bind them should also be easily repulped.

Traditional hot-melt adhesives use resins that are insoluble in water, creating what are known in the industry as stickies, which must be removed during the repulping process to convert pulp into recycled paper. Stickies are often challenging to remove if they do not meet specific size requirements. As the packaging industry drives towards developing more sustainable products, hot-melt adhesive formulators need options for resins that exhibit strong adhesive performance while being easy to repulp.

Eastman AQ™ Polyester Resins for Repulpable Adhesives

Eastman developed AQ™ sulfopolyester resins that are water-dispersible and ideal for repulpable hot-melt adhesives. These resins are based on thermoplastic, aromatic polymers with anionic sulfonate groups. They are available in grades with low Tg, high tack, minimal odor, indirect food contact approval, and inherent water dispersibility without the need for emulsifiers, cosolvents, or dispersants. Additionally, these resins are compatible with several common hot-melt adhesive additives, such as tackifiers like rosin acids and esters, hydrocarbon resins, and glycol plasticizers. Besides these additives, they are compatible with acrylic polymers, polyester urethanes, and waxes.

These features lead to the following benefits in repulpable hot-melt adhesive formulations:

- Excellent performance characteristics for adhesion, strength, and durability

- Easy and complete dispersion in water for repulping processes

Below is a starter formulation using Eastman AQ™ 1950 for a hot-melt adhesive for multiwall bag end seams. Performance data for the hot-melt adhesive was compared against a polyethylene-based hot-melt adhesive.

Starter Formulation and Test Data for Eastman AQ™ Resin in Hot-Melt Adhesives

| Component | Wt (%) |

| Eastman AQ™ 1950 | 70.0 |

| Picco™ 6100 | 20.0 |

| Benzoflex™ 352 | 9.7 |

| IRGANOX® 1010 | 0.3 |

| Test Properties | Eastman AQ™ Hot-Melt Adhesive | PE-Based Hot-Melt Adhesive |

| Viscosity (at 177°C, cPs) | 18,450 | 32,100 |

| Ring and ball softening point | 102 | 106 |

| SAFT (°C) | 85 | 99 |

| PAFT (°C) | 60 | 68 |

| Repulpability (73°F, pH 11, %) | 100 | N/A |

Adhesive Performance Characteristics

As seen above, the hot-melt adhesive formulation featured similar performance in terms of shear and peel adhesion failure test temperature, indicating that the overall cohesive and adhesive strength provided by the AQ™ 1950 resin is comparable to that of PE-based resins. AQ™ sulfopolyester resins also exhibit high resistance to extreme temperature and mechanical stress. They also have excellent adhesion to treated polyethylene and polypropylene substrates, making them useful beyond paper-based packaging.

AQ™ sulfopolyester resins are also extremely heat stable, showing a minimal change in color and visual appearance over time. Thus, adhesive formulations made with AQ™ resins have longer pot lives at elevated temperatures, more consistent performance over a run, and less applicator downtime due to clogging. Below is an image of the AQ™ 1950 resin before and after being aged at 80°C for 100 hours in a forced-air oven, demonstrating excellent thermal stability.

| AQ™ 1950 Resin (Initial) |

AQ™ 1950 Resin (Aged) |

|

|

Repulpability

The adhesive made with the AQ™ 1950 resin was also completely repulpable under alkaline conditions. Not only does this make the overall recycling process for paper-based packaging easier, but it potentially allows for cost savings. For example, some repulping processes require nonrepulpable adhesive residues to be at least a certain length, width, and thickness to be removed by mechanical separation processes. By completely dispersing in water, the adhesives made using AQ™ 1950 bypass this minimum size and thickness requirement, allowing for smaller adhesive areas to be applied. This leads to lower material requirements and cost savings while maintaining the necessary level of adhesion.

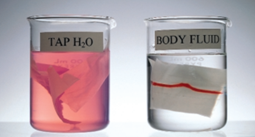

While readily dispersible in water, Eastman AQ™ polyesters also carry the unique property of being nondispersible in ionic solutions. Below is an image of two nonwoven materials bonded with a red-dyed adhesive made with Eastman AQ™ polyester. These were then placed in beakers for eight hours to demonstrate dispersibility. The beaker on the left contained tap water, and the one on the right contained a 0.2M ionic solution.

|

From the above, it is apparent that Eastman AQ™ polyesters are inherently water dispersible and not dispersible in ionic media. This property offers benefits for other hot-melt adhesive applications that require repulpability but resistance to degradation when in contact with bodily fluids, as in the case of adhesives used in medical applications.

Summary

With the rise in paper-based packaging and a larger focus on recyclability, repulpable hot-melt adhesives offer a sustainable solution for packaging manufacturers. Formulators of these adhesives require the right resins to meet demands in both performance and ease in the repulping process. Eastman AQ™ sulfopolyester resins, such as AQ™ 1950, possess unique attributes of high strength, additive compatibility, heat stability, and inherent water dispersibility, making them ideal resins for repulpable hot-melt adhesives. Click below to ask a question about Eastman AQ™ resins and request a sample today.

IRGANOX® is a registered trademark of BASF.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States