Conclusion

Select Your Region

Worldwide regulatory standards such as the United States CARB Tier 3/LEV III and European 6d-TEMP-EVAP-ISC mandate strict limits on the release of fuel vapors into the atmosphere. Evaporative emissions stem from the following five primary sources.

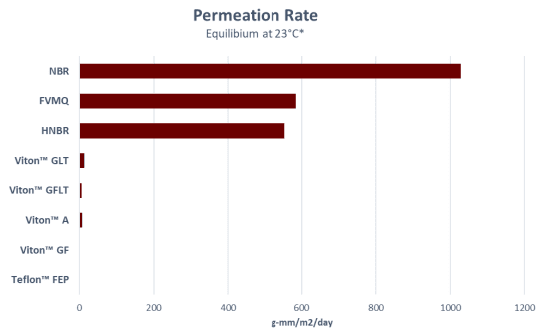

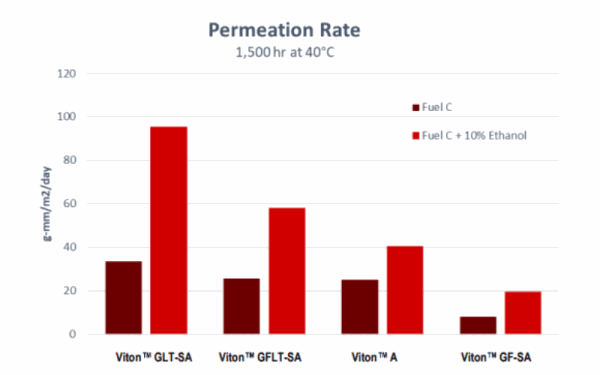

Historically, traditional elastomers like nitrile rubber (NBR) have been used for sealing applications; however, due to new regulatory standards, it is no longer a viable option due to its limited permeation resistance. Viton™ FKM materials exhibit exceptional resistance to fuel permeation, even in the presence of ethanol-blended fuels (e.g., E10).

Grade

|

Fluorine Content (%)

|

Permeation Resistance

|

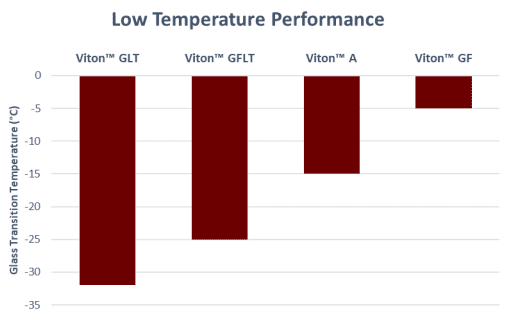

Low-Temperature Performance

|

|---|---|---|---|

Viton™ GLT

|

~64

|

Very good

|

−32°C (−26°F)

|

Viton™ GFLT

|

~67

|

Excellent

|

−25°C (−13°F)

|

Viton™ AL

|

~66

|

Very good

|

−19°C (−2°F)

|

Viton™ A

|

~66

|

Very good

|

−15°C (5°F)

|

Viton™ F

|

~70

|

Excellent

|

−5°C (23°F)

|

Conclusion

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States