Select Your Region

Improve Metal Coatings with Tyzor® Titanates

Industrial Coatings and Metal Protection

A variety of metals and alloys are used in industrial applications, ranging from small metal parts and equipment to structural components to electrical wires. These metals include steel, iron, aluminum, copper, and many others that often have industrial coatings and treatments applied to protect them from corrosion, abrasion, and everyday wear and tear. The protective properties of the coating need to be maximized to create a long service life and high performance of the metal.

Tyzor® organic titanates are highly reactive chemical compounds widely used within the industrial metal coatings industry to provide various functional benefits characteristic of high-quality metal coatings. In terms of chemistry, Tyzor® titanates are nontoxic, organometallic chemicals with ligands attached to a titanium or zirconium atom through an ester linkage. These ligands create high potential reactivity with materials that constitute coating systems and metal substrates to provide functional benefits.

How Is Tyzor® Used in Metal Coating and Treatment Applications?

Tyzor® organic titanates can be used in solvent-based, water-based, or solvent-free industrial treatment and coating formulations as a binder, surface modifier, adhesion promoter, or catalyst to improve the protection and integrity of metal surfaces. The benefits of Tyzor® are outlined below by functionality.

Binder

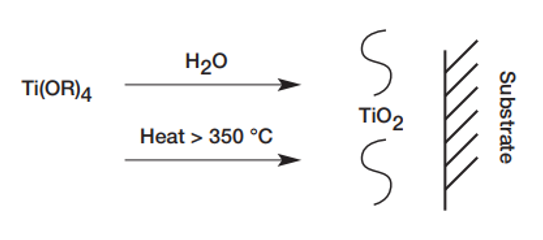

Tyzor® is an ideal inorganic binder and cobinder used to form a continuous metal oxide layer that protects metal surfaces. It can be combined with other organometallic compounds in a sol–gel process to form thin layers of inert titanium oxide films that increase surface hardness and resist water, heat, and scratches. Typically, these layers are formed when Tyzor® solutions are vapor deposited, dipped, or sprayed to substrates and then subjected to a controlled hydrolysis process under heat. Tyzor® can also be used to bind sacrificial metal pigments used in metal coatings for corrosion protection. The mechanism by which Tyzor® forms films on metallic materials is depicted below. |

Benefits

- Corrosion protection

- Improved water, heat, and scratch resistance

- Increased surface hardness

Adhesion Promoter

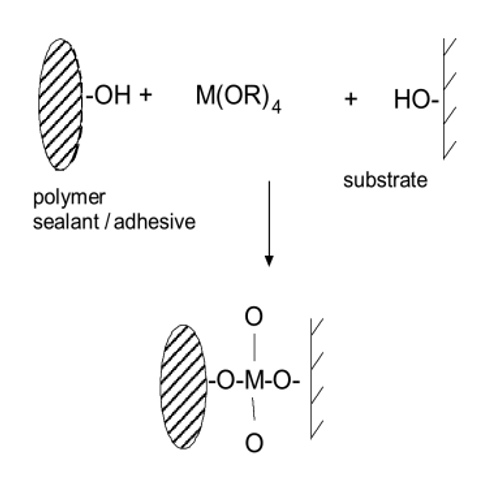

For an industrial coating to be effective, it must first and foremost adhere well to the surface it needs to protect. Tyzor® titanates are widely used to increase the adhesion of coatings to various materials, including organic polymers, inorganic surfaces, and, of course, metal surfaces. Tyzor® can be applied as a primer or added to coating formulations to improve binding between metal surfaces and industrial coatings. Not only is adhesion improved, but the coating also gains higher resistance to chemical attack. The mechanism in which Tyzor® promotes adhesion to materials such as metal substrates is depicted below. |

Benefits

- Improved adhesion of coatings to metal

- Increased water and chemical resistance

- Enhanced mechanical properties of the coating

Catalyst and Curing Aid

Tyzor® titanates are well-known cross-link polymers with hydroxyl and carboxyl functionality. This feature makes them especially useful as catalysts and curatives that help speed up curing and improve the durability of metal coating formulations that contain hydroxyl or carboxyl group chemistry. Tyzor® is typically formulated into coating systems as an additive in this application.Benefits

- Accelerated cure speed

- Improved coating cohesion

- Increased coating durability

Surface Treatment Additive

When used with phosphates and silicates, Tyzor® can help increase the efficiency of phosphatizing processes for steel, zinc, aluminum, cadmium, zirconium, and manganese materials. In particular, Tyzor® helps create a finer crystalline surface structure that enhances corrosion resistance and coating adhesion. Following the phosphatization process, Tyzor® may also be incorporated into an aqueous rinse to form a water-insoluble deposit on the metal surface. In this application, Tyzor® is used as a nontoxic alternative to chromium to improve corrosion resistance.

Benefits

- Superior corrosion resistance

- Safer alternative to toxic chromium treatments

Where Is Tyzor® Used?

Wire Enamels

Film and insulation properties of wire coating formulations can be improved with the addition of Tyzor®. Ring cracks in high-temperature wire can lead to catastrophic failure. Wire coatings formulated with Tyzor® titanates show improved thermal resistance, leading to fewer ring cracks in high-temperature wire.

Industrial Coatings

Sheet metal, small metal parts, metal equipment, and metal coils can be coated with Tyzor® to form titanium metal oxide layers that protect from corrosion and increase surface toughness. Tyzor® may also be used as a coating adhesion promoter or a coating binder that facilitates cross-linking, creating coatings with higher resistance to heat, corrosion, and abrasion.

Pretreatments

Tyzor® can be used in rinses and pretreatments to increase coating adhesion and corrosion resistance. Phosphatized metal surfaces treated with Tyzor® may be treated again with a Tyzor® solution to further increase corrosion resistance by forming deposits insoluble in water.

Grade Recommendations

Selecting the proper Tyzor® grade for the metal coatings industry is based on specific end-use requirements, system type, and coating process. Better control of reactivity and optimized performance for metal coatings can be achieved by choosing the proper grade. The Tyzor® product line consists of two main types of chemistry: reactive alkoxides that are highly sensitive to moisture and stable chelates that are more tolerant of moisture. As some coating systems may or may not be based on waterborne systems and some desirable functions that Tyzor® offers are based on controlled hydrolysis procedures, moisture tolerance is an important consideration. A list of grade recommendations for industrial coatings and metal treatments based on end-use application is provided below.| Application | ||||||

|---|---|---|---|---|---|---|

Moisture Reactivity

|

Highest

|

High

|

High

|

Medium

|

Medium

|

Low

|

| Industrial Paint | ✅

|

✅

|

||||

| Wire Coating | ✅

|

✅

|

||||

| Heat Resistant Paint | ✅

|

✅

|

✅

|

|||

| Corrosion Protection | ✅

|

✅

|

✅

|

✅

|

||

| Water-Based Paint | ✅

|

✅

|

✅

|

Summary

Tyzor® organic titanates are ideal binders and additives for metal coatings and treatments applied to parts, equipment, sheets, and surfaces. They help increase durability and protection against corrosion, heat, and moisture. Contact us below to discuss your metal coating application and request more information. We will be happy to recommend the right grade for your formulation.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - Canada