Select Your Region

RAL Color Standards — Rilsan® Powders

RAL Color Powder Coatings

If you're in the market for a high-quality powder coating solution, you may have heard of Rilsan® Powder Coatings. These coatings are known for their superior quality, durability, and versatility, making them a popular choice across a range of industries.

What are Rilsan® Fine Powders?

Rilsan® fine powders from Arkema are a type of renewably sourced, bio-based thermoplastic powder coating used to protect and enhance the surface of metal parts and components. These coatings are made from a unique polymer known as polyamide 11, which is derived from renewable castor oil. Polyamide 11 is a highly durable, long-lasting material resistant to chemicals, abrasion, and harsh impact, making it an ideal coating material for various applications.

Why Use Rilsan® Fine Powder Coatings?

Rilsan® fine powders offer a range of features and benefits that make them a popular choice for industrial and commercial applications. Some of the key advantages of Rilsan® powder coatings including the following:

|

Durability: Rilsan® powder coatings are highly durable and resistant to impact, abrasion, scratching, staining and even harsh chemicals. |

Search Our RAL - Rilsan® Powders Data Base

How to Apply Rilsan® Powder Coatings

Rilsan® powder coatings can be applied to metal surfaces using a variety of methods including electrostatic spray, fluidized bed and more.

Electrostatic spray application is a process where the powder coating is electrically charged and then sprayed onto a prepared metal surface. The powder particles are attracted to the metal and quickly adhere to the surface, forming a uniform and continuous coating layer. The coated parts are then cured in an oven at high temperatures, which causes the powder particles to melt and fuse to form a solid, durable coating that protects the component from corrosion, scratching, staining and more. Learn More about Electrostatic Spray Application Here ►

Fluidized bed dip coating is another application process to adhere the thermoplastic powders to the surface of a pre-treated metal part. Metal components are heated prior to the initial coating and then passed into a vessel full of the thermoplastic powders suspended via continuous air flow. This liquid-like collection of powder adheres to component surfaces and results in a consistent coating thickness, even on complex metal pieces. Learn More about Fluidized Bed Application Here ►

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - United States

RAL 9011

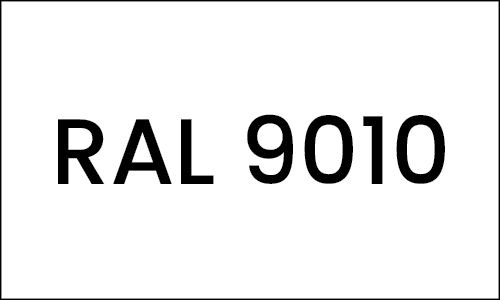

RAL 9011 RAL 9010

RAL 9010 RAL 9016

RAL 9016 RAL 8024

RAL 8024 RAL 7040

RAL 7040 RAL 7024

RAL 7024 RAL 7001

RAL 7001 RAL 7000

RAL 7000 RAL 5015

RAL 5015 RAL 5013

RAL 5013 RAL 5012

RAL 5012 RAL 5010

RAL 5010 RAL 5005

RAL 5005 RAL 5003

RAL 5003 RAL 5002

RAL 5002 RAL 1016

RAL 1016 Uncolored

Uncolored